RMC est Sinae ferrum immaculatum liminis fundendi ut ferrum incorruptum machinatum habeat sicut per tractus et requisita tua, usus est impulsor centrifugae sentinae clausae.

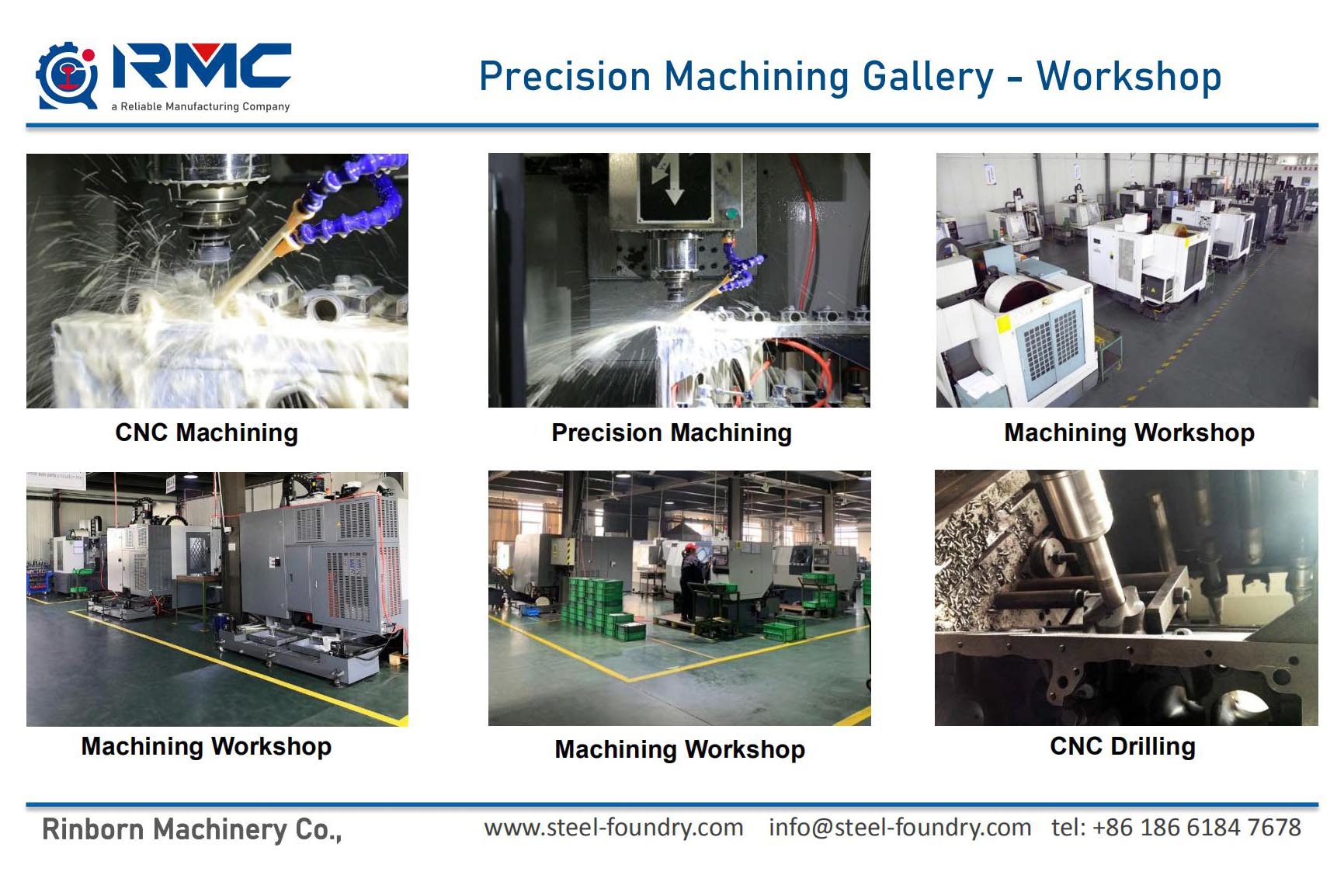

CNC machiningrefertur ad processum machinum procedendum ab Computerised Control Numero (CNC pro brevi). CNC adiuvatur ut accurationem altam et constantem cum minore labore dispendio attingat. Machinatio quaevis variarum processuum est in quibus particula rudis materiae in ultimam figuram et magnitudinem desideratam inciditur per processum materialem remotionem moderatum. Processus qui hoc thema commune habent, materiales remotiones moderantur, hodie in communi noti sunt vestibulum subtractivae, in distinctione a processibus additi materialis moderati, qui noti sunt fabricandi additivi.

Prorsus id quod "moderata" definitionis pars importat, variari potest, sed fere semper usum instrumentorum machinarum (praeter instrumenta instrumenta potestatis et manus). Haec est processus multorum metallorum productorum fabricandi, sed etiam in materiis uti lignis, plasticis, ceramicis et compositis adhiberi potest. Machinatio CNC machinis varios processus comprehendit, ut molendinum, conversionem, lassitudinem, artem, honationem, stridorem... etc.

| CNC Precision Machining Capabilities | ||||

| Facilities | quantitas | Magnitudo dolor | Annua capacitas | Generalis cura |

| Vertical Machining Center (VMC) | 48 sets | 1500mm 1000mm 800mm | (VI) tonn vel (XXX) pieces | ±0.005 |

| Horizontal Machining Centre (VMC) | 12 sets | 1200mm 800mm × 600mm | MM talenta vel (C) pieces | ±0.005 |

| CNC Machina | 60 sets | Max vertens dia. φ600mm | (V) talenta vel (DC) pieces | |

| Excutive Standard of Casting Tolerance: ISO 8062 2013, ISO 2768, GOST 26645 (Russia) or GBT 6414 (Sina). | ||||

Machinatio centrum e machina CNC milling enascitur. Maxima differentia a machina CNC milling est quod machinarum centrum facultatem habet instrumenta machinandi automatice commutandi. Instruendo instrumenta ad diversos usus in instrumento emporium, instrumenta machinis super fusum mutari possunt ab ipso instrumento mutante in uno clamping ut plures machinis notas cognoscas.

CNC machinarum centrum est instrumentum machinae automated altae efficientiae, quod ex instrumento mechanico et systemate CNC componitur et ad partes complexas expediendas apta est. CNC machinarum centrum est currently unum e instrumentorum machinarum late CNC machinarum in mundo cum valida facultate processus comprehensiva. Plus potest perficere processus contentus postquam workpiece coagmentatur uno tempore. Princeps accurate processus est. Nam batch officinarum cum difficultate mediae processus, eius efficientia est 5-10 temporum quae instrumenti ordinarii, praesertim multi processus, qui ordinario instrumento perfici non potest, aptiores sunt ad singulas partes processus cum formis multiplicioribus et exquisitis exigentiis vel altae. pro parva et media massa multiplex varietatum productio. Munera moliendi, taedii, exercendi, percunctandi et scindendi fila in una cogitatione colligit, ita ut varietatem instrumentorum technologicorum habeat.

Machinatio centra collocantur in machinis horizontalibus et verticalibus secundum situm localem in machinis fusum. Indicatur secundum processum usus: centrum machinandi taediosum et milling, centrum machining compositum. Secundum specialem functionum classificationem, exstant: una officina, duplex opificina et multi- plicandi centrum. Machinatio centra cum axe simplici, axe duali, axe trium, axe quarto, axe quinque-, et convertibili capite, etc.

Machinatio CNC machinæ genus est machinæ machinæ a CNC machinis qualia machinæ centra provectioris quæ habent summum finem 5 axem machinæ centrum, 4 axem duplicatum machinæ centrum, vel CNC gyratoriæ quæ ad CNC convertendi centrum habent facultatem mutandi magis. quam XV serratores intra se tenentes trabea; CNC apparatus molendi et CNC terebratio et centra percussio. Praecisio machinis iaciendi ferri differt a machinis ferris. Subtilitas iectionis iam satis exactam figuram desiderati consequi, sic multas machinationes servat comparatas cum machinis ex ferro profile directe. Ob hanc etiam causam, machinis superficiei ac machinis cibaria ante jactationem rite considerare solemus. Procuratio nostra regularis est elaborare rudis emissionem trahendi cum machinis trahendi ut machinam aream definias et prebendam machinis edendam.

RMC collocatio fundamenti fundorum instructa cum 4 axi machinarum centris, 15 clusorum CNC rotarum torni et 3 mutatoriarum machinarum cnc molentium, una cum adiutorio versatili communi versatili, molendi, Ictibus, exercendis et stridoribus machinis, machinandi fere omnes facultatem habemus. genera ferri dejectiones.

| Equivalent Grade dejectus Alloy Steel ex diversis mercatis | |||||||||

| GROUPS | AISI | W-stoff | DIN | BS | SS | AFNOR | UNE/IHA | JIS | UNI |

| Humilis Alloy Steel | 9255 | 1.0904 | 55 Si 7 | 250 A 53 | 2090 | 55 S 7 | 56Si7 | - | 5SSi8 |

| 1335 | 1.1167 | 36 Mn 5 | 150 M 36 | 2120 | 40 M 5 | 36Mn5 | SMn 438(H). | - | |

| 1330 | 1.1170 | 28 Mn 6 | 150 M 28 | - | 20 M 5 | - | SCMn1 | C28MN | |

| P4 | 1.2341 | X6 CrMo 4 | - | - | - | - | - | - | |

| 52100 | 1.3505 | 100 Cr 6 | 534 A 99 | 2258 | 100 C 6 | F.131 | SUJ 2 | 100Cr6 | |

| A204A | 1.5415 | 15 Mo 3 | 1501 240 | 2912 | 15 D 3 | 16 Mo3 | STBA 12 | 16Mo3 KW | |

| 8620 | 1.6523 | 21 NiCrMo 2 | 805 M 20 | 2506 | 20 NCD 2 | F.1522 | SNCM 220(H) | 20NiCrMo2 | |

| 8740 | 1.6546 | 40NiCrMo22 | 311-Type 7 | - | 40 NCD 2 | F.129 | SNCM 240 | 40NiCrMo2(KB) | |

| - | 1.6587 | 17CrNiMo6 | 820 A 16 | - | 18 NCD 6 | 14NiCrMo13 | - | - | |

| 5132 | 1.7033 | 34 Cr 4 | 530 A 32 | - | 32 C 4 | 35Cr4 | SCr430(H) | 34Cr4(KB) | |

| 5140 | 1.7035 | 41 Cr 4 | 530 A 40 | - | 42 C 2 | 42 Cr 4 | SCr 440 (H). | 40Cr4 | |

| 5140 | 1.7035 | 41 Cr 4 | 530 A 40 | - | 42 C 2 | 42 Cr 4 | SCr 440 (H). | 41Cr4 KB | |

| 5140 | 1.7045 | 42 Cr 4 | 530 A 40 | 2245 | 42 C 4 TS | F.1207 | SCr 440 | - | |

| 5115 | 1.7131 | 16 MnCr 5 | (527 M 20) ; | 2511 | 16 MC 5 | F.1516 | - | 16MnCr5 | |

| 5155 | 1.7176 | 55 Cr 3 | 527 A 60 | 2253 | 55 C 3 | - | HAUS 9(A) | 55Cr3 | |

| 4130 | 1.7218 | 25 CrMo 4 | 1717CDS 110 | 2225 | 25 CD 4 | F.1251/55Cr3 | SCM 420 / SCM430 | 25CrMo4(KB) | |

| 4135 (4137). | 1.7220 | 35 CrMo 4 | 708 A 37 | 2234 | 35 CD 4 | 34 CrMo 4 | SCM 432 | 34CrMo4KB | |

| 4142 | 1.7223 | 41 CrMo 4 | 708 M 40 | 2244 | 42 CD 4 TS | 42 CrMo 4 | SCM 440 | 41 CrMo 4 | |

| 4140 | 1.7225 | 42 CrMo 4 | 708 M 40 | 2244 | 40 CD 4 | F.1252 | SCM 440 | 40CrMo4 | |

| 4137 | 1.7225 | 42 CrMo 4 | 708 M 40 | 2244 | 42 CD 4 | F.1252 | SCM 440 | 42CrMo4 | |

| A387 12-2 | 1.7337 | 16 CrMo 4 4 | 1501 620 | 2216 | 15 CD 4.5 | - | - | 12CrMo910 | |

| - | 1.7361 | 32CrMo12 | 722 M 24 | 2240 | 30 CD 12 | F.124.A | - | 30CrMo12 | |

| A182 F-22 | 1.7380 | 10 CrMo9 10 | 1501 622 | 2218 | 12 CD 9, 10 | F.155/ TU.H | - | 12CrMo9 10 | |

| 6150 | 1.8159 | 50 CrV 4 | 735 A 50 | 2230 | 50 CV 4 | F.143 | HAUSTUS 10 | 50CrV4 | |

| - | 1.8515 | 31 CrMo 12 | 722 M 24 | 2240 | 30 CD 12 | F.1712 | - | 30CrMo12 | |

| - | - | - | - | - | - | - | - | - | |

| Medium Alloy Steel | W1 | 1.1545 | C105W1 | BW1A | 1880 | Y 105 | F.5118 | SK 3 | C100 KU |

| L3 | 1.2067 | 100Cr6 | BL 3 | (2140) | Y 100 C 6 | F.520 L | - | - | |

| L2 | 1.2210 | 115 CrV 3 | - | - | - | - | - | - | |

| P20 + S | 1.2312 | 40 CrMnMoS 8 6 | - | - | 40 CMD 8 +S | X210CrW12 | - | - | |

| - | 1.2419 | 105WCr6 | - | 2140 | 105W C 13 | F.5233 | SKS 31 | 107WCr5KU | |

| O1 | 1.2510 | 100 MnCrW 4 | BO1 | - | 90MnWCrV5 | F.5220 | (SK53) | 95MnWCr5KU | |

| S1 | 1.2542 | 45 WCrV 7 | BS1 | 2710 | 55W20 | F.5241 | - | 45WCrV8KU | |

| 4340 | 1.6582 | 34 CrNiMo 6 | 817 M 40 | 2541 | 35 NCD 6 | F.1280 | SNCM 447 | 35NiCrMo6KB | |

| 5120 | 1.7147 | 20 MnCr 5 | - | - | 20 MC 5 | - | - | - | |

| - | - | - | - | - | - | - | - | - | |

| Instrumentum et High Alloy Steel | D3 | 1.2080 | X210 Cr 12 | BD3 | 2710 | Z200 C 12 | F.5212 | SKD 1 | X210Cr13KU |

| P20 | 1.2311 | 40 CrMnMo 7 | - | - | 40 CMD 8 | F.5263 | - | - | |

| H13 | 1.2344 | X40CrMoV 5 1 | BH13 | 2242 | Z 40 CDV 5 | F.5318 | SKD 61 | X40CrMoV511KU | |

| A2 | 1.2363 | X100 CrMoV 5 1 | BA2 | 2260 | Z 100 CDV 5 | F.5227 | SKD 12 | X100CrMoV51KU | |

| D2 | 1.2379 | X155 CrMoV 12 1 | BD2 | 2310 | Z 160 CDV 12 | F.520.A | SKD11 | X155CrVMo121KU | |

| D4(D6) | 1.2436 | X210 CrW 12 | BD6 | 2312 | Z 200 CD 12 | F.5213 | SKD 2 | X215CrW121KU | |

| H21 | 1.2581 | X30WCrV9 3 | BH21 | - | Z 30 WCV 9 | F.526 | SKD5 | X30WCrV 9 3 KU | |

| L6 | 1.2713 | 55NiCrMoV 6 | - | - | 55 NCDV 7 | F.520.S | SKT4 | - | |

| M 35 | 1.3243 | S6/5/2/5 | BM 35 | 2723 | 6-5-2-5 | F.5613 | SKH 55 | HS6-5-5 | |

| M 2 | 1.3343 | S6/5/2 | BM2 | 2722 | Z 85 WDCV | F.5603 | SKH 51 | HS6-5-2-2 | |

| M 7 | 1.3348 | S2/9/2 | - | 2782 | 2 9 2 | - | - | HS2-9-2 | |

| HW 3 | 1.4718 | X45CrSi 9 3 | 401 S 45 | - | Z 45 CS 9 | F.3220 | SUH1 | X45CrSi8 | |

| - | 1.7321 | 20 MoCr 4 | - | 2625 | - | F.1523 | - | 30CrMo4 | |

| Princeps tensile Fortitudo Ferro | A128 (A) | 1.3401 | G-X120 Mn 12 | BW10 | 2183 | Z 120 M 12 | F.8251 | SCMnH 1 | GX120Mn12 |

Facultates of *Investment mittentes aliquet pretium:

• Max Size: 1,000 mm × 800 mm × 500 mm

• Pondus dolor: 0.5 kg - 100 kg

• Capacitas annui: 2,000 tons

• Materiae vinculi ad Testam Aedificium: Silica Sol, Vitrum Aquarum et earum mixtiones.

• Tolerantiae: De Request.

CommodaTractatus Iaculatio Components:

- Superficies optima et lenis meta

- Stricta tolerantiae dimensiva.

- Complexae et intricatae figurae cum consilio flexibilitate

- Facultas igitur tenuiores ejiciendi parietes tenues component

- Lata selectio metallica et admixtionum (ferrarum et non-ferrarum)

— Draft in fingit consilio non requiritur.

- Reducere necessitatem machinis secundae.

— Humilis materia perditio.

| Materia enim elit mittentes etCNC Machiningad RMC Foundry | |||

| Categoria | Sina Gradus | US Gradus | Germania Grade |

| Ferritic Steel | 1Cr17, 022Cr12, 10Cr17; | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Martensitic Steel | 1Cr13, 2Cr13, 3Cr13, 4Cr13; | 410, 420, 430, 440B, 440C . | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125. |

| Austenitic immaculatam ferro | 06Cr19Ni10, 022Cr19Ni10; 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4406, 1.4408, 1.4409, 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581; 1.4582, 1.4584; |

| Praecipitatio Hardening Diver | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex Steel | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A; A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| Princeps Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Instrumentum Steel | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Calor resistens Steel | 20Cr25Ni20, 16Cr23Ni13; 45Cr14Ni14W2Mo | 309, 310, CK 20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Nickle-basi Alloy | PRAECEL-C, PRAECEL-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35. -1, INCOLOY600; INCOLOY625 | 2.4815, 2.4879, 2.4680 | |

| aluminium Alloy | ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Aeris Alloy | H96, H85, HPb63-3; HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Cobaltum basi Alloy | UMC50, 670, Grade 31 | 2.4778 | |

Machinatio praecisio dicitur, machinatio CNC perquam accurata in tolerantia geometrica et tolerantia dimensiva attingere potuit. Cum nostris machinis CNC et Machiningis Horizontalibus Centris (HMC) et Centris Vertical Machining (VMC), omnes fere gradus tolerantiae requisitae tuae occurrere possumus.

| INVESTMENT IACTATIO TOLERATIO | |||

| Unciarum | Millimeters | ||

| Dimension | tolerantia | Dimension | tolerantia |

| Ad 0.500 | ±.004" | Ad 12.0 | ± 0.10mm |

| 0.500 ad 1.000" | ±.006" | 12.0 ad 25.0 | ± 0.15mm |

| 1.000 ad 1.500" | ±.008" | 25.0 ad 37.0 | ± 0.20mm |

| 1.500 ad 2.000" | ±.010" | 37.0 ad 50.0 | ± 0.25mm |

| 2.000 ad 2.500" | ±.012" | 50.0 ad 62.0 | ± 0.30mm |

| 2.500 ad 3.500" | ±.014" | 62.0 ad 87.0 | ± 0.35mm |

| 3.500 ad 5.000" | ±.017" | 87.0 ad 125.0 | ± 0.40mm |

| 5.000 ad 7.500" | ±.020" | 125.0 to190.0 | ± 0.50mm |

| 7.500 ad 10.000" | ±.022" | 190.0 ad 250.0 | ± 0.57mm |

| 10.000 ad 12.500" | ±.025" | 250.0 ad 312.0 | ± 0.60mm |

| 12.500 ad 15.000 | ±.028" | 312.0 ad 375.0 | ± 0.70mm |