At RMC Foundry, most of the stainless steel castings are produced by lost wax investment casting process because of the high accuracy. Stainless steel (SS for short) is the abbreviation of stainless and acid-resistant steel. It is called stainless steel that is resistant to weak corrosive media such as air, steam, and water. Corrosion steel is called acid-resistant steel. We can pour many sub-categories stainless steel such as Ferritic Stainless Steel, Martensitic Stainless Steel, Austenitic Stainless Steel, Precipitation Hardening Stainless Steel as well as Duplex Stainless Steel (DSS). Austenitic stainless steel, which refers to the group of stainless steel with an austenitic structure at room temperature, is the mostly used kind of stainless for investment castings. Austenitic stainless steel is one of the five classes of stainless steel by crystalline structure (along with ferritic, martensitic, duplex and precipitation hardened). In some areas, the austentite stainless steel is also called the 300 series stainless steel. When the steel contains about 18% Cr, 8%-25% Ni, and about 0.1% C, it has a stable austenite structure. Austenitic chromium-nickel stainless steel includes the famous 18Cr-8Ni steel and the high Cr-Ni series steel developed by adding Cr and Ni content and adding Mo, Cu, Si, Nb, Ti and other elements on this basis. Austenitic stainless steel is non-magnetic and has high toughness and plasticity, but its strength is low, and it is impossible to strengthen it through phase transformation. It can only be strengthened by cold working. If elements such as S, Ca, Se, Te are added, it has good properties of machinability.

-

Precipitation Hardening Stainless Steel Casting

-

Cast Steel Part from China Foundry

-

Corrosion Resistant Stainless Steel Casting Product

-

Stainless Steel Lost Wax Casting Foundry

-

Austenitic-Ferritic Duplex Stainless Steel Casting Product

-

Centrifugal Pump Vane Impeller

-

Silica Sol Lost Wax Casting Product

-

China AISI 304 Stainless Steel Investment Casting Impeller

-

Custom Stainless Steel Impeller by Investment Casting

-

CNC Machined Stainless Steel Cast Parts

-

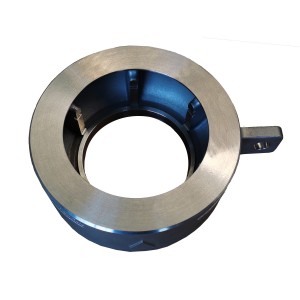

Stainless Steel AISI 316 Investment Casting Pump Housing

-

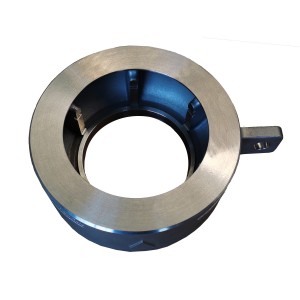

Stainless Steel Investment Casting Pump Body