Excellent quality Precision Casting Parts - Custom Cast Iron Sand Casting – RMC Foundry Detail:

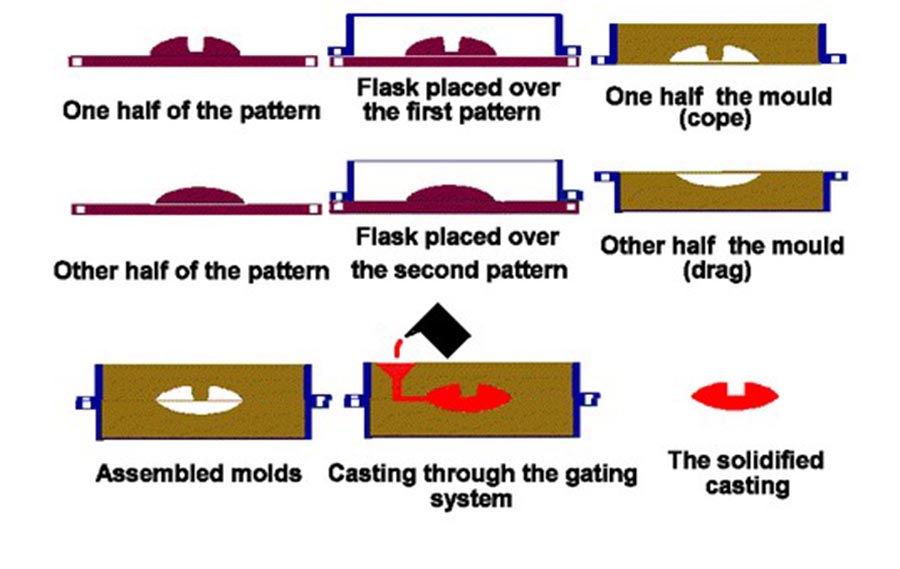

Sand casting foundry is the metal foundry mainly using sand casting process to produce metal castings made of gray iron, ductile iron, cast steel, stainless steel, brass and aluminum alloys. Sand casting process is mainly used to produce grey iron castings and ductile iron castings. It could be divided into green sand casting, furan resin pre-coated sand (shell molding) casting based on different sand materials. Cast iron sand castings have many advantages such as low costs, complex design, high effeciency, and good quality. Sand casting process is a suitable and good choice for iron casting parts unless the special or very high requirements have to be matched.

RMC Foundry can pour iron castings using our green sand mold, heat shell mold and no-bake casting process up to tons of finished weight in gray iron castings and ductile iron castings, and up to hundreds of kilograms in steel castings and stainless steel castings. RMC can produce casting parts in a wide variety of materials, including grey iron, ductile iron, stainless steel, carbon steel, wear-resistant steel, and heat-resistant steel based on different standards from China and overseas.

RMC Foundry’s experience in creating high-end sand castings from high-grade materials and consisting of complex geometries is beyond comparison. In our high-tech facilities, we offer both machine and manual molding operations in our resin sand casting processes. We produce parts in low-to-high volumes and pour castings ranging from 0.5 kg to tons. Our green sand castings range from 0.5 kgs to 800 kgs

Product detail pictures:

Related Product Guide:

With a positive and progressive attitude to customer's interest, our enterprise continually improves our products excellent to meet the wants of customers and further focuses on safety, reliability, environmental requirements, and innovation of Excellent quality Precision Casting Parts - Custom Cast Iron Sand Casting – RMC Foundry, The product will supply to all over the world, such as: Paris , Slovakia , Czech republic , It using the world's leading system for reliable operation, a low failure rate, it suitable for Argentina customers choice. Our company is situated within the national civilized cities, the traffic is very convenient, unique geographical and economic conditions. We pursue a people-oriented, meticulous manufacturing, brainstorm, build brilliant" business philosophy. Strict quality management, perfect service, reasonable price in Argentina is our stand on the premise of competition. If necessary, welcome to contact us by our website or phone consultation, we'll be happy to serve you.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.