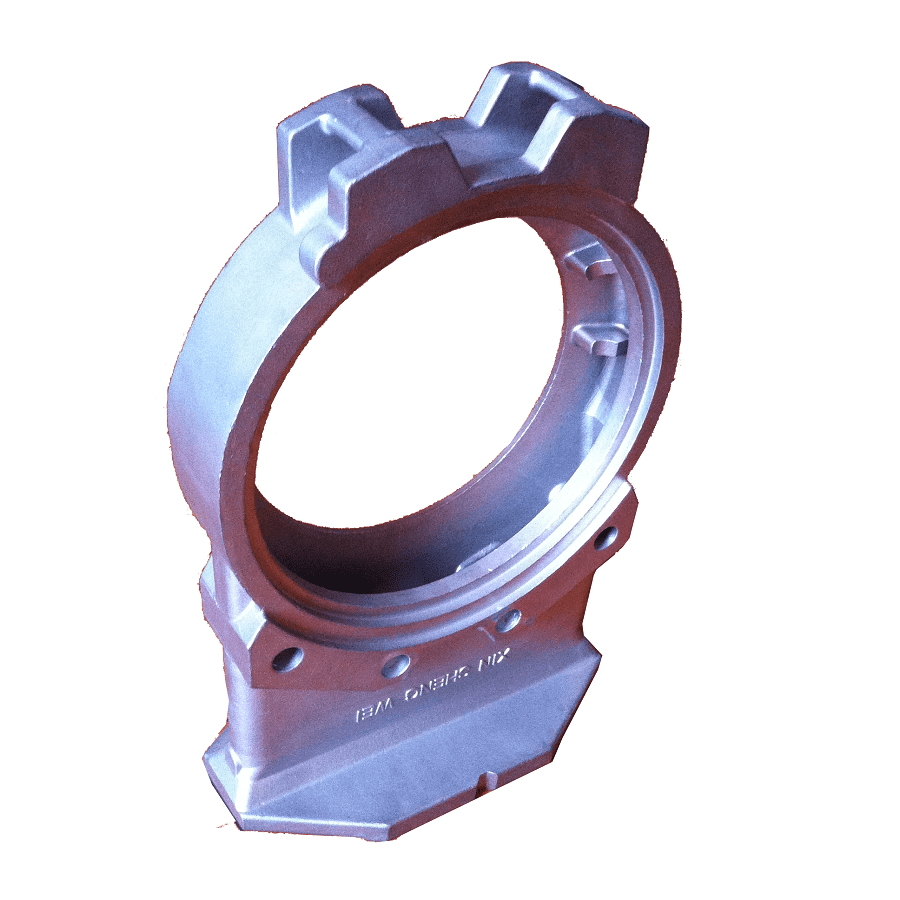

Bottom price Metal Investment Casting - Stainless Steel 316 / 1.4408 Casting Valve Disc – RMC Foundry Detail:

OEM custom stainless steel investment castings from China foundry with CNC machining, assembly and surface treatment services.

Stainless Steel: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4408, 1.4571 and other stainless steel grade.

Why You Choose RMC Foundry for Stainless Steel Castings?

• Full solution from one single supplier ranging customized pattern design to finished castings and secondary process including CNC machining, heat treatment and surface treatment.

• Costdown proposals from our professional engineers based on your unique requirement.

• Short leadtime for prototype, trial casting and any possible technical improvement.

• Bonded Materials: Silica Col, Water Glass and their mixtures.

• Manufacturing flexibility for small orders to mass orders.

• Strong outsourcing manufacturing capabilities.

| Investment Casting Technical Data at RMC | |

| R&D | Software: Solidworks, CAD, Procast, Pro-e |

| Lead Time for Development and Samples: 25 to 35 days | |

| Molten Metal | Ferritic Stainless Steel, Martensitic Stainless Steel, Austenitic stainless steel, Precipitation Hardening Stainless Steel, Duplex Stainless Steel |

| Carbon Steel, Alloy Steel, Tool Steel, Heat Resistant Steel, | |

| Nickle-base Alloy, Aluminium Alloy, Copper-base Alloy, Cobalt-base Alloy | |

| Metal Standard | ISO, GB, ASTM, SAE, GOST EN, DIN, JIS, BS |

| Material for Shell Building | Silica Sol (Precipitated Silica ) |

| Water Glass (Sodium Silicate) | |

| Mixtures of Silica Sol and Water Glass | |

| Technical Parameter | Piece Weight: 2 gram to 200 kilo gram |

| Max Dimension: 1,000 mm for Diameter or Length | |

| Min Wall Thickness: 1.5mm | |

| Casting Roughness: Ra 3.2-6.4, Machining Roughness: Ra 1.6 | |

| Tolerance of Casting: VDG P690, D1/CT5-7 | |

| Tolerance of Machining: ISO 2768-mk/IT6 | |

| Inner Core: Ceramic Core, Urea Core, Water Soluble Wax Core | |

| Heat Treatment | Normalizing, Tempering, Quenching, Annealing, Solution, Carburization. |

| Surface Treatment | Polishing, Sand / Shot Blasting, Zinc Plating, Nickel Plating, Oxidation Treatment, Phosphating, Powder Painting, Geormet, Anodizing |

| Dimension Testing | CMM, Vernier Caliper, Inside Caliper. Depth Gage, Height Gage, Go/No go Gage, Special Fixtures |

| Chemical Inspection | Chemical Compostion Analysis (20 chemical elements), Cleanliness Inspection, X-ray Radiographic Inspection, Carbon-Sulfur Analyser |

| Physical Inspection | Dynamic Balancing, Static Blancing, Mechanical Properties (Hardness, Yield Strength, Tensile Strength), Elongation |

| Production Capacity | More than 250 tons per month, more than 3,000 tons annually. |

Product detail pictures:

Related Product Guide:

Our team through qualified training. Skilled professional knowledge, powerful sense of support, to satisfy the support desires of consumers for Bottom price Metal Investment Casting - Stainless Steel 316 / 1.4408 Casting Valve Disc – RMC Foundry, The product will supply to all over the world, such as: Sri Lanka , Sierra Leone , Georgia , Wide selection and fast delivery to suit your needs! Our philosophy: Good quality, great service, keep improving. We've been looking forward that more and more oversea friends join in our family for further development near the future!

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!