Super Lowest Price Ductile Iron Investment Casting Foundry – Lost Wax Casting Product of Cast Carbon Steel – RMC Foundry Detail:

China OEM custom carbon steel castings by lost wax investment casting and CNC precision machining. Available grade from low carbon steel, medium carbon steel to high carbon steel according to different specifications.

Carbon alloy is the group of iron-carbon alloy with rare of other chemical elements such as Si, Mn, P and S. According to the level of carbon content, carbon steel for casting is generally divided into low carbon steel, medium carbon steel and high carbon steel. The cast carbon steels of all countries in the world are generally classified according to their strength, and corresponding grades are formulated. At the same temperature, the fluidity of molten steel with different carbon content is different. Because steels with different carbon content have different degrees of development in dendrites. The greater the temperature interval of the crystallization zone (the temperature difference between the liquidus line and the solidus line), the more developed the dendritic crystals of the carbon steel, that is, the worse the fluidity of the molten steel, which results in the ability of the molten steel to fill the mold.

Regarding the chemical composition of carbon steel, except for phosphorus and sulfur, there are no restrictions or only upper limits on other chemical elements. Under the above premise, the chemical composition of cast carbon steel is determined by the foundry according to the required mechanical properties.

The heat treatment methods of carbon steel castings are usually annealing, normalizing or normalizing + tempering. For some high carbon steel castings, quenching and tempering can also be used, that is, quenching + high temperature tempering, so as to improve the comprehensive mechanical properties of carbon steel castings. Small carbon steel castings can be directly quenched and tempered from the as-cast state. For large-scale or complex-shaped carbon steel castings, it is appropriate to perform quenching and tempering treatment after normalizing treatment.

The Advantages of Investment Casting:

✔ Excellent and smooth surface finish

✔ Tight dimensional tolerances.

✔ Complex and intricate shapes with design flexibility

✔ Capability to cast thin walls therefore a lighter casting component

✔ Wide selection of cast metals and alloys (ferrous and non-ferrous)

✔ Draft is not required in the molds design.

✔ Reduce the need for secondary machining.

✔ Low material waste.

| INVESTMENT CASTING TOLERANCES | |||

| Inches | Millimeters | ||

| Dimension | Tolerance | Dimension | Tolerance |

| Up to 0.500 | ±.004″ | Up to 12.0 | ± 0.10mm |

| 0.500 to 1.000” | ±.006″ | 12.0 to 25.0 | ± 0.15mm |

| 1.000 to 1.500” | ±.008″ | 25.0 to 37.0 | ± 0.20mm |

| 1.500 to 2.000” | ±.010″ | 37.0 to 50.0 | ± 0.25mm |

| 2.000 to 2.500” | ±.012″ | 50.0 to 62.0 | ± 0.30mm |

| 2.500 to 3.500” | ±.014″ | 62.0 to 87.0 | ± 0.35mm |

| 3.500 to 5.000” | ±.017″ | 87.0 to 125.0 | ± 0.40mm |

| 5.000 to 7.500” | ±.020″ | 125.0 to190.0 | ± 0.50mm |

| 7.500 to 10.000” | ±.022″ | 190.0 to 250.0 | ± 0.57mm |

| 10.000 to 12.500” | ±.025″ | 250.0 to 312.0 | ± 0.60mm |

| 12.500 to 15.000 | ±.028″ | 312.0 to 375.0 | ± 0.70mm |

| Excutive Standard of Casting Tolerance: ISO 8062 2013, ISO 2768, GOST 26645 (Russia) or GBT 6414 (China). Dimensional Casting Tolerances Grade (DCTG): 4 ~6 and Geometrical Casting Tolerances Grade (GCTG): 3 ~ 5. | |||

The Steps of Investment Casting Process:

During the investment casting process, a wax pattern is coated with a ceramic material, which, when hardened, adopts the internal geometry of the desired casting. In most cases, multiple parts are cast together for high efficiency by attaching individual wax patterns to a central wax stick called a sprue. The wax is melted out of the pattern – which is why it is also known as the lost wax process – and molten metal is poured into the cavity. When the metal solidifies, the ceramic mold is shaken off, leaving the near net shape of the desired casting, followed by finishing, testing and packaging.

| Equivalent Grade of Carbon Steel | |||||||||

| Description | AISI | W-stoff | DIN | BS | SS | AFNOR | U.N.E. / I.H.A. | JIS | UNI |

| Low Carbon Steel | A570-36 | 1.0038 | RSt 37-2 | 4360 40 C | 1311 | E 24-2 Ne | - | SS 34 | Fe 360B FN |

| A36 | 1.0044 | St 44-2 | 4360 43 A | 1411 | NFA 35-501 E 28 | - | - | - | |

| A573-81 65 | 1.0116 | St 37-3 | 4360 40 B | 1312 | E 24-U | - | - | Fe37-3 | |

| 1006 | 1.0201 | St 36 | - | 1160 | Fd 5 | - | - | - | |

| A515-65 | 1.0345 | H I | 1501 161 | 1330 | A 37 CP | F.1110 | SGV 410 | - | |

| 1015 | 1.0401 | C 15 | 080 M 15 | 1350 | CC 12 | F.111 | S 15 C | 080 M 15 | |

| 1020 | 1.0402 | C22 | 050 A 20 | 1450 | CC20 | F.112 | - | C20C21 | |

| - | 1.0425 | H II | - | 1432 | A 42 CP | A42 RCI | SGV 410 | Fe 410 1KW | |

| 1213 | 1.0715 | 9 SMn 28 | 230 M 07 | 1912 | S 250 | 11SMn28 | SUM 22 | CF9SMn28 | |

| (12L13) | 1.0718 | 9 SMnPb 28 | - | 1914 | S 250 Pb | 11SMnPb28 | SUM 22 L | CF9SMnPb28 | |

| - | 1.0723 | 15 S 20 | 210 A 15 | 1922 | - | F.210.F | SUM 32 | - | |

| 1140 | 1.0726 | 35 S 20 | 212 M 36 | 1957 | 35 MF 6 | F.210.G | - | - | |

| 1146 | 1.0727 | 45 S 20 | 212 M 44 | 1973 | 45 MF 4 | - | - | - | |

| 1215 | 1.0736 | 9 SMn 36 | 240 M 07 | - | S 300 | 12 SMn 35 | SUM 25 | CF 9 SMn 36 | |

| - | 1.0765 | - | - | - | - | - | - | 36SMnPb14 | |

| 1010 | 1.1121 | Ck 10 | 045 M 10 | 1265 | XC 10 | F.1510 | S 10 C | C10 | |

| - | 1.1121 | St 37-1 | 4360 40 A | 1300 | - | - | S 10 C | - | |

| 1022 | 1.1133 | GS-20Mn 5 | 120 M 19 | 1410 | 20 M 5 | F.1515 | SMnC 420 | G22Mn3 | |

| 1015 | 1.1141 | Ck 15 | 080 M 15 | 1370 | XC 18 | F.1511 | S 15 Ck | 080 M 15 | |

| 1025 | 1.1158 | Ck 25 | 070 M 26 | 1450 | XC 25 | F.1120 | S 25 C | C25 | |

| 1018 | - | - | - | - | - | - | SS400 | Fe 360 B | |

| Medium Carbon Steel | A662 C | 1.0436 | ASt 45 | 1501 224 | 2103 | A 48 FP | - | - | - |

| 1035 | 1.0501 | C 35 | 060 A 35 | 1550 | CC 35 | F.113 | S 35 C | C35 | |

| 1035 | 1.0501 | C 35 | 080 M 36 | 1550 | CC 35 | F.113 | S 35 C | C35 | |

| 1045 | 1.0503 | C 45 | 080 M 46 | 1650 | CC45 | F.114 | S 45 C | C45 | |

| 1040 | 1.0511 | C 40 | 080 M 40 | - | AF 60 C 40 | F.114.A | - | C40 | |

| 1055 | 1.0535 | C 55 | 070 M 55 | 1655 | AF 70 C 55 | F.115 | S 55 C | C55 | |

| - | 1.0570 | St 52-3 | 4360 50 B | 2132 | E 36-3 | - | SM 490 A, B, C | Fe 510 | |

| A738 | 1.0577 | ASt 52 | 1501 224 | 2107 | A 52 FP | - | - | - | |

| 1039 | 1.1157 | 40Mn4 | 150 M 36 | - | 35 M 5 | - | - | - | |

| 1035 | 1.1181 | Ck 35 | 060 A 35 | 1572 | XC 38 | F.1130 | S 35 C | C35 | |

| 1035 | 1.1183 | Cf 35 | 080 M 36 | 1572 | XC 38 TS | - | S 35 C | C36 | |

| 1045 | 1.1191 | Ck 45 | 808 M 46 | 1672 | XC 45 | F.1140 | S 45 C | C45 | |

| 1055 | 1.1203 | Ck55 | 070 M 55 | - | XC 55 | F.1203 | S55 C | C50 | |

| 1050 | 1.1213 | Cf 53 | 060 A 52 | 1674 | XC 48 TS | - | S 50 C | C53 | |

| 1045 | 1.1730 | C45W | En 43 B | 1672 | Y342 | F.1140 | - | - | |

| A572-60 | 1.8900 | StE 380 | 4360 55 E | 2145 | - | - | - | FeE390KG | |

| - | 1.8905 | StE 460 | HP 6 | - | - | - | - | ||

| High Carbon Steel | 1060 | 1.0601 | C60 | 060 A 62 | - | CC55 | - | - | C60 |

| 1064 | 1.1221 | Ck 60 | 060 A 62 | 1678 | XC 65 | F.1150 | S 58 C | C60 | |

| 1070 | 1.1231 | Ck 67 | 070 A 72 | 1770 | XC 68 | F.5103 | - | C70 | |

| 1080 | 1.1248 | Ck 75 | 060 A 78 | 1774 | XC 75 | F.5107 | - | - | |

| 1095 | 1.1274 | Ck 101 | 060 A 96 | 1870 | XC 100 | F.5117 | SUP 4 | - | |

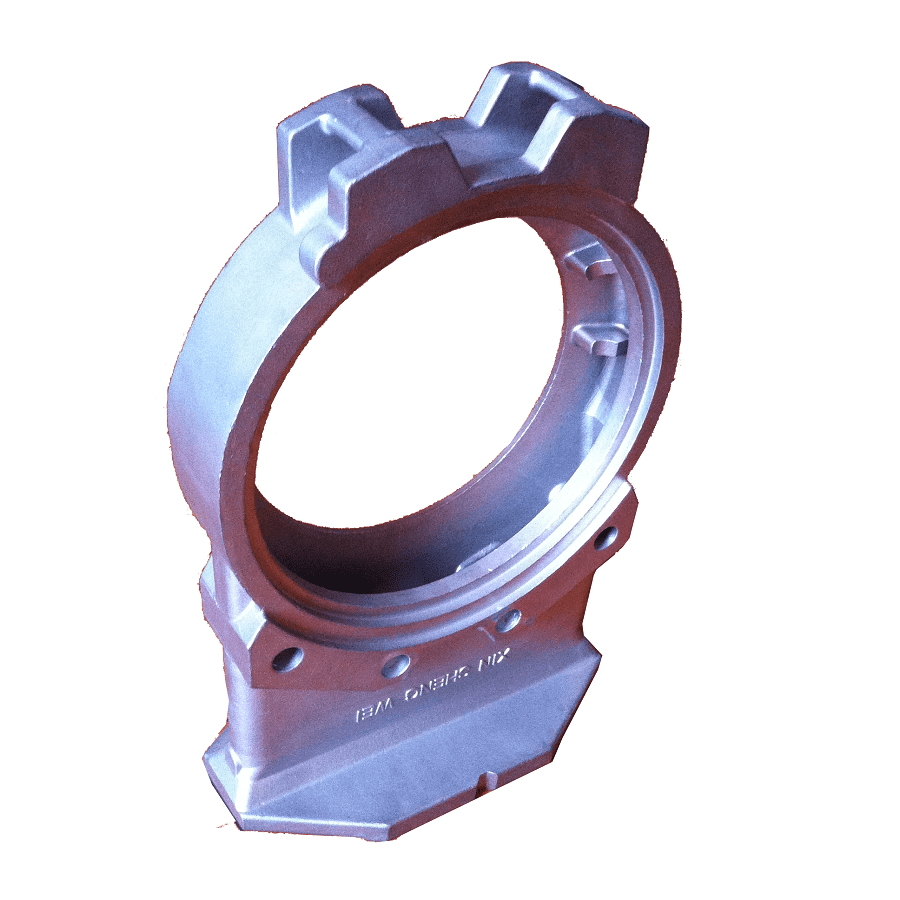

Product detail pictures:

Related Product Guide:

We usually perform being a tangible workforce making sure that we will give you the most beneficial excellent plus the finest selling price for Super Lowest Price Ductile Iron Investment Casting Foundry – Lost Wax Casting Product of Cast Carbon Steel – RMC Foundry, The product will supply to all over the world, such as: St. Petersburg , Mongolia , Sri Lanka , With the aim of "compete with good quality and develop with creativity" and the service principle of "take customers' demand as orientation", we will earnestly provide qualified products and good service for domestic and international customers.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.

-

Factory Cheap Hot Vacuum Casting Manufacturer -...

-

Special Design for Precision Machining - Cast ...

-

Ordinary Discount Ductile Iron Casting Supplier...

-

OEM/ODM China Stainless Steel Investment Castin...

-

2020 High quality Shell Mold Casting Products -...

-

China Manufacturer for Cnc Machining Services -...