As we all know, investment casting produces the castings with precision accuracy and good finish. However, during the production process of investment casting, there are many possible common casting defects. Based on our engineering experience and advanced equipment, we can find a way to prevent such problems by analyzing the causes. Below, we introduce several common casting defects and their causes and prevention methods. Hope this article is helpful for our customers to understand the problems and to our colleagues, this analysis could help you prevent the possible casting defects.

Undercast and cold barrier

1. Problem description:

Undercasting often lacks meat locally in the thin wall of the casting or away from the inner runner, and its edge is arc-shaped. The cold partition is that two strands of molten metal are not completely fused and there are obvious joints.

2. Cause:

1) Low molten metal pouring temperature and mold temperature

2) Pouring speed is slow or runner setting is unreasonable, metal flow is too long

3) The wall thickness of the casting is too thin, and the flow of molten metal is poor

4) Cut off during pouring

3. Preventive measures:

1) Increase molten metal pouring temperature and mold temperature

2) Increase the pouring speed or increase the number or area of the inner runner to reduce the flow of molten metal

3) Increase the pressure head of the pouring riser to prevent cut-off during pouring

Shrinkage

1. Description of the problem:

It can only be found by X-ray inspection. The surface shrinkage can be found by fluorescence or staining inspection. In severe cases, it can be found after sand blowing.

2. Cause:

1) The casting structure is unreasonable, and the hot spots are too much or too big

2) The heat capacity of the pouring riser is small, which fails to form sequential solidification, or the pressure head is small, which reduces the feeding capacity

3) The mold temperature is low, the cooling rate is fast, and the feeding channel is blocked

3. Preventive measures:

1) Improve casting structure and reduce hot spots

2) Set the riser reasonably, or add a feeding rib that can be removed by processing methods, increase the pressure head, so that the investment castings can be solidified sequentially under the action of a certain pressure head

3) Appropriately increase the pouring temperature and mold temperature to slow down the cooling rate

Hot crack

1. Problem description:

Irregular intergranular cracks are produced on the surface or inside, and the surface is oxidized. It can be seen after severe sand cleaning, and only mild processing or penetration inspection can be found.

2. Causes:

1) It is related to the composition of the alloy, the content of carbon and silicon is high, the temperature range of the liquid-solid phase is large, and hot cracking is easy

2) Low mold temperature, poor retreatability and fast cooling rate

3) The thickness of the casting varies greatly, and the transition fillet is too small

3. Preventive measures:

1) For alloys or steels that are prone to hot cracks, their carbon and silicon content should be controlled as far as possible to the middle and lower limits

2) Increase the mold temperature during pouring, slow down the cooling rate of the casting, or reduce the strength of the mold shell

3) Add anti-cracking process ribs at the joints of the thickness of the castings, or increase the transition fillets

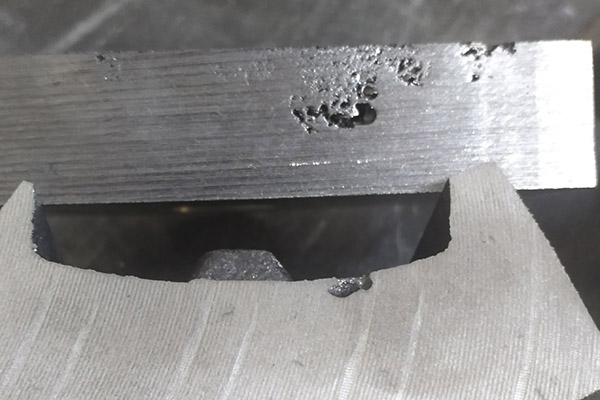

Cold Crack

Name and Characteristics:

There are continuous penetrating cracks on the casting. A shiny surface or a slightly oxidized surface appears at the fracture.

Causes

1. During the cooling process of the casting, shrinkage is hindered, resulting in thermal stress and phase change stress, and these stresses exceed the strength of the material in the elastic state and cause fracture.

2. In the process of cleaning the shell, cutting the gate, riser or during adjusting, the casting with residual stress is subjected to external force to cause fracture.

Prevention Methods

1. Add stiffening ribs at the cold cracks to improve the retreatability of the shape, thereby reducing shrinkage resistance and casting stress.

2. In the post-casting process, avoid severe impact between castings.

Blowhole

Name and Characteristics

There are obvious or inconspicuous holes with smooth inner surface on the casting.

Causes

1. Poor air permeability of the mold shell, which makes it too late for the gas in the cavity to be discharged during pouring.

2. Insufficient firing of the shell shape, resulting in insufficient removal of mold material residues and gas-producing materials in the shell material.

3. The metal liquid gas content is too high, causing poor deoxidation.

4. The setting of the pouring system is unreasonable, causing human gas to be involved in pouring.

Prevention Methods

1. Improve the air permeability of the shell and add vents if necessary.

2. Fully fired shell.

3. Improve deoxidation methods.

4. Improve the gating system.

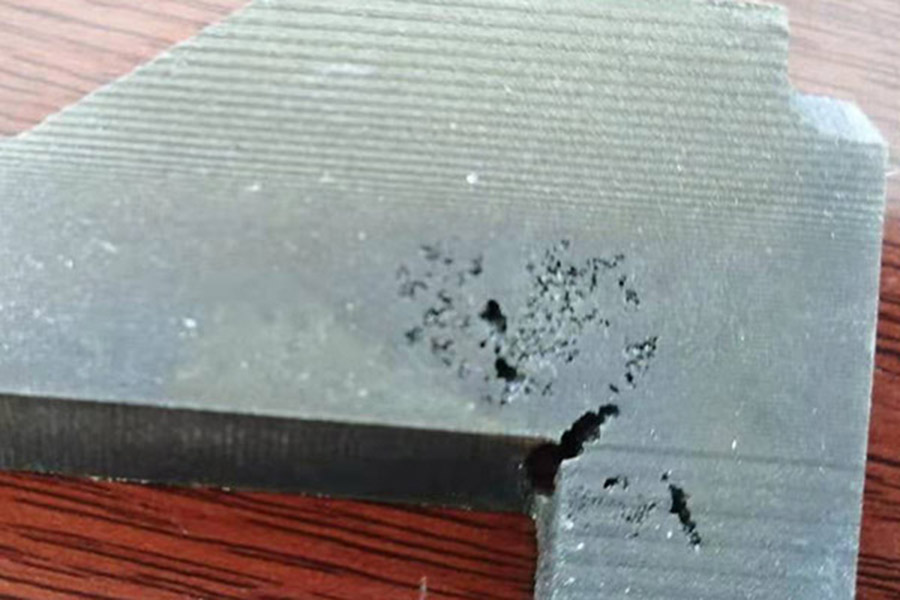

Casting Pitting

Name and Characteristics

There are dense dot-like pits on the surface of the casting.

Causes

1. When ethyl silicate is used as a binder, the incomplete hydrolysate is in the coating process, the indoor relative humidity is too low, so that the hydrolysate cannot be further hydrolyzed, and the "white frost" is precipitated after roasting.

2. When water glass is used as a binder, the residual salt in the mold shell reacts with the molten metal to form a pit.

3. The molten metal is poorly deoxidized or the slag is not cleaned during tapping.

Prevention Methods:

1. When using ethyl silicate as a binder, appropriately increase the amount of water added and increase the relative humidity of the paint studio to minimize residual incomplete hydrolysates.

2. When using water glass as a binder, clean the shell with acidified water after dewaxing.

3. Change the surface coating to silica sol as the binder.

4. During smelting, strengthen deoxidation and slag removal.

Casting Subcutaneous Pinhole

Name and Characteristics

After the surface of the casting is polished, the tiny black spots appear. This phenomenon mostly occurs in nickel-chromium stainless steel.

Causes:

1. Too much recycled material is used during metal molten, or the recycled material has not been treated properly.

2. During the smelting process, the molten metal is oxidized or the molten metal absorbs gas, resulting in insufficient deoxidation.

3. The impurity content of the shell material is too high, or the bonding agent and the molten metal have a chemical reaction.4. Unreasonable setting of gating system.

Prevention Methods:

1. Control or reduce the amount of recycled material, and the recycled material needs to be used after sand blowing or shot blasting.

2. Strictly control the smelting process and strengthen deoxidation.

3. Use fused corundum, zircon sand and silica sol or ethyl silicate paint.

4. Try to use bottom injection method for pouring and increase vent holes.

Sticky Sand

Name and Characteristics

There is a sticky sand layer near the runner or inside the casting, and there are raised burrs or pits after sand blowing.

Causes

1. The impurity content of the refractory powder used in the coating surface layer is too high, and these impurities react with the molten metal to form a low melting point eutectic.

2. The pouring temperature is too high, especially the steel grades containing Al, Ti and other elements, which causes a chemical reaction between the molten metal and the silica.

3. The setting of the gating system is unreasonable, and a large amount of molten metal flows through the inner runner, causing local overheating.

Prevention Methods

1. Use fused steel jade or zircon sand instead of silica sand, and try not to use water glass as a binder.

2. Appropriately lower the pouring temperature.

3. Add an inner runner to adjust the heat balance and reduce local overheating.

Dilatant

Name and Characteristics

Local swelling on the larger plane of the casting, this phenomenon is more obvious when using water glass as a binder.

Causes

1. The casting structure is unreasonable and the plane area is too large.

2. The shell has low strength at high temperature and cannot withstand the pressure of molten metal.

Prevention Methods

1. Improve the structure, add process ribs or process holes on the plane.

2. When making the shell, use shell materials with less impurities and high refractoriness, or increase the thickness of the shell.

Slag

Name and Characteristics

There is slag or other debris in the inside or surface of the casting. Internal inclusions need to be detected by X-ray or magnetic inspection.

Causes

1. The slag material is too thin and is not cleaned before tapping.

2. The debris on the tapping trough of the crucible was not cleaned up before tapping and was brought into the molten metal.

3. When casting, the slag retention is not good, and the slag enters the cavity with the molten metal.

Prevention Methods

1. Adjust the composition of the slag material before tapping to increase the viscosity of the slag material and make it easier to remove the slag.

2. Clean up the debris in the front trough of the steel to avoid bringing impurities into the molten metal in the ladle.

3. Before casting, the molten cast teel should be properly sedated to facilitate the slag floating.

4. Take a teapot pouring ladle with a slag stopper or a ceramic filter.

Decarburization

Name and characteristics

The carbon content of the surface layer of the casting is lower than that of the matrix.

Causes

1. During casting, the temperature of the molten metal and the mold is high, and the solidification rate of the casting is slow.

2. The depth of the decarburization layer is related to the atmosphere of the cooling environment of the casting. The greater the concentration of the oxidizing atmosphere, the more serious the decarburization.

Prevention Methods

1. Appropriately reduce the casting temperature and mold temperature to speed up the cooling rate.

2. Artificially create a reducing atmosphere around the mold, such as adding barium carbonate and charcoal powder to the mold.

Post time: Jan-22-2021