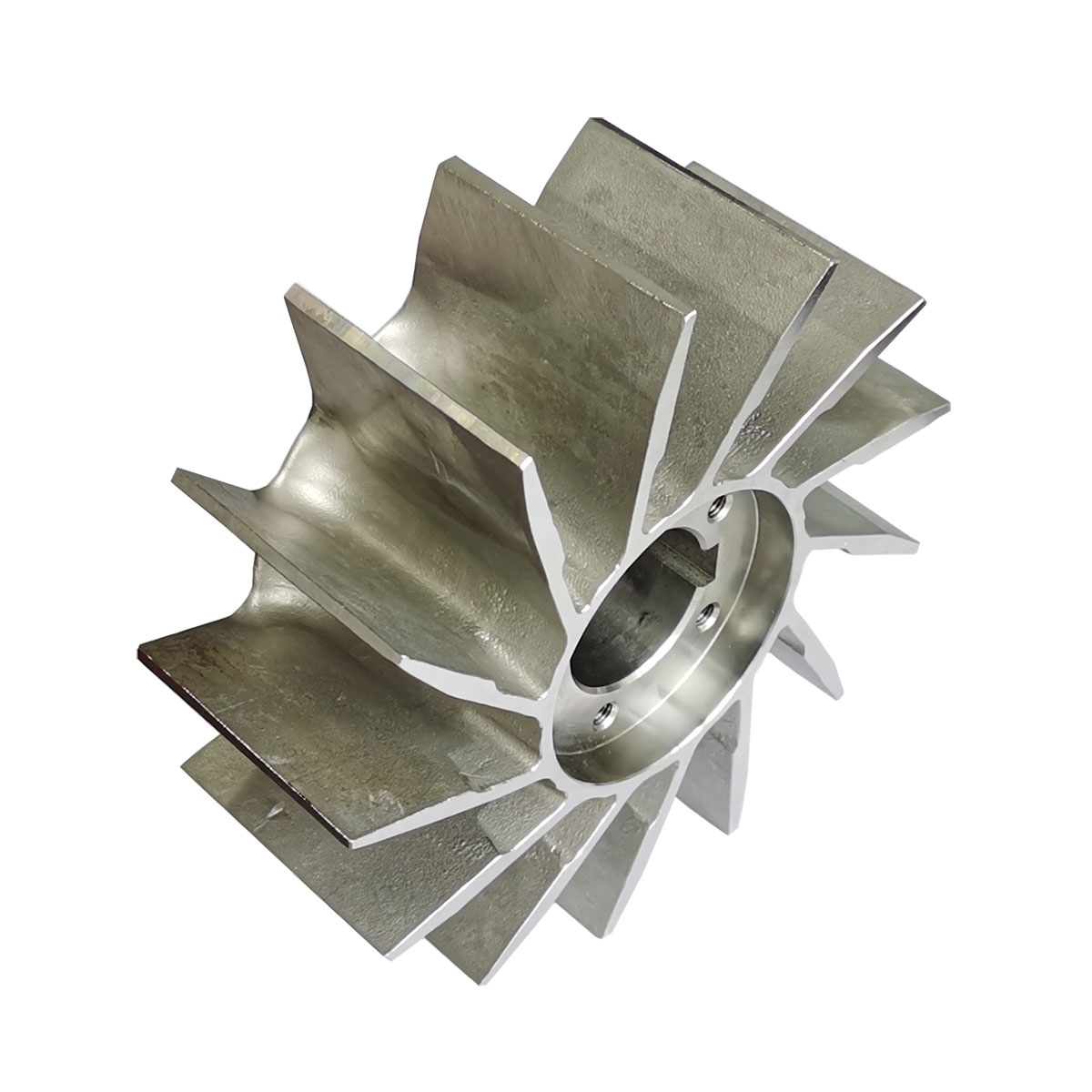

Low price for Gray Iron No Bake Casting - Centrifugal Pump Vane Impeller – RMC Foundry Detail:

The impeller refers to a wheel disc with moving blades. In a centrifugal pump, the impeller refers to a rotating body with blades that transfers energy to the liquid.

The blades of centrifugal pump impellers are generally backward curved blades. There are two types of blades: cylindrical and twisted. The use of twisted blades can reduce the load of the blades, improve the suction performance of the centrifugal pump, and improve the anti-cavitation ability, but the manufacturing is difficult and the cost is high.

The centrifugal pump for refining and chemical industry requires the impeller to be cast or fully welded integral impeller. The development of welded impellers is mostly used for chemical special centrifugal pumps made of metal materials with poor casting properties (such as iron and its alloys). The geometric accuracy and surface finish of the welded impeller are better than those of the cast impeller, which is beneficial to improve the efficiency of the centrifugal pump.

According to the processing method, the impeller can be divided into riveted type, welded type and integral type. The integrally formed impeller mainly refers to the precision casting process and other special processes. The precision casting process saves both man-hours and materials, but due to the complex shape of the impeller and the high processing requirements, it is difficult to ensure that the castings are free of pores and impurities.

RMC Foundry can manufacture various types of impellers using the precision casting process (investment casting) as well as CNC precision machining. We can manufacture high-precision, corrosion-resistant impellers from austenitic stainless steel, duplex stainless steel, precipitation hardened stainless steel, and nickel-based alloys.

At present, the basic types of centrifugal pump impellers are flow channel type (single flow channel, double flow channel), vane type (closed type, open type), spiral centrifugal type and swirl type.

1. Channel Type Impeller

The flow channel impeller is a curved flow channel from the inlet to the outlet. This type of impeller is suitable for conveying liquids containing large particles of impurities or long fibers. Because this type of impeller has excellent anti-clogging properties. But his disadvantage is that the anti-cavitation performance is weaker than other forms.

2. Vane Impeller

The semi-open and open impellers in the vane impeller are easy to cast, and easy to maintain and clean up the impurities blocked in the conveying process. However, its disadvantage is that the gap between the inner wall of the pressurized water and the blade under the abrasion of solid particles increases during the transportation process, which reduces the operating efficiency of the pump, and the stability of the flow state of the liquid in the flow channel is destroyed because of the increase in the gap. , make the pump vibrate, this type of impeller is not easy to transport medium containing large particles and long fibers. The closed impeller has high operating efficiency and can run smoothly for a long time. The axial thrust of the pump is small, but the closed impeller is easy to be wound, and it is not easy to transport sewage media containing large particles or long fibers.

3. Spiral Centrifugal Impeller

Spiral centrifugal impellers have twisted blades that extend axially from the suction port on a tapered hub body. The conveyed liquid will not hit any part of the pump when it flows through the blades, so there is no damage to the pump, and at the same time, it is not destructive to the conveyed liquid. Due to the propulsion of the screw, the suspended particles have a strong passability, so this type is adopted. Impeller pumps are suitable for pumping media containing large particles and long fibers.

4. Swirl Impeller

The swirling impeller is all or part of the impeller that is retracted to the flow channel of the pressurized water chamber, which has good anti-clogging performance. The particles flow in the water pressure chamber under the impetus of the vortex generated by the rotation of the impeller, and the movement of the suspended particles does not generate energy, and exchanges energy with the liquid in the flow channel. During the flow process, the suspended particles or long fibers do not contact the worn blades, the blades are more worn, and the gap is not enlarged due to abrasion. It is suitable for pumping media containing large particles and long fibers.

The vane impellers used in centrifugal pumps can be divided into four forms: (a) closed type; (b) front half-open type; (c) rear half-open type; (d) open type

1. Closed impeller

The closed impeller consists of blades and front and rear cover plates. The closed impeller has high efficiency and is difficult to manufacture, and is most used in centrifugal pumps. It is suitable for conveying clean liquids with low viscosity and no particles, such as clean water and solutions.

2. Semi-open impeller

The semi-open impeller generally has two structures: one is the front semi-open type, which is composed of the rear cover plate and the blades. The impeller efficiency of this structure is low, and a sealing ring with adjustable clearance is required to improve the efficiency; the other is the rear cover plate and the blade. The semi-open type consists of a front cover plate and a blade. Since the same sealing ring as the closed impeller can be applied, the efficiency is basically the same as that of the closed impeller, and the blade also has a (back blade or auxiliary impeller) seal in addition to conveying liquid. effect. The semi-open impeller is suitable for conveying liquids containing suspended solids such as solid particles and fibers. The semi-open impeller is less difficult to manufacture, low in cost, and has strong adaptability.

3. Open impeller

The open impeller has only the blades and the blade reinforcing ribs, and there is no impeller with front and rear cover plates. The impeller has low efficiency and less applications, and is mainly used to transport liquids with high viscosity and slurry liquids.

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for Low price for Gray Iron No Bake Casting - Centrifugal Pump Vane Impeller – RMC Foundry, The product will supply to all over the world, such as: Hamburg , Montpellier , Manila , If any item be of interest to you, please let us know. We will try our best to satisfy your requirements with high quality products, the best prices and prompt delivery. Please feel free to contact us at any time. We will reply you when we receive your inquiries. Please note that samples are available before we start our business.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.

-

Manufactur standard Carbon Steel V Process Cast...

-

Good quality Carbon Steel Investment Casting - ...

-

Super Purchasing for Aluminium Alloy Foundry - ...

-

factory low price Stainless Steel Precision Cas...

-

Quality Inspection for Casting Supplier - Cust...

-

Manufacturer for Lost Foam Casting Factory - A...