Hot Selling for Stainless Steel Sand Casting Foundry - Custom Aluminium Alloy Casting Product – RMC Foundry Detail:

Custom Aluminium alloy casting products by sand casting process and CNC machining.

Steps of Sand Casting Production Process

1. Making Patterns

Resin or aluminum patterns will be necessary for green sand casting process. Without patterns, the production for castings will be impossible. Sometimes, wooden patterns could be used for small quantity production, but for mass production, resin or aluminum patterns will be more suitable.

2. Molding Process

The green sand molding could be made by three methods typically, including manual molding, molding machine and automatic molding equipment. The manual molding is a traditional molding method, but it still exists because of its capability for large castings at lower costs. The molding machine method could save manpower and produce better quality castings, but it can not produce large castings because of its size limitation of sand boxes.

3. Iron Melting and Pouring

Melting could be done by medium frequency electrical induction furnaces, which could keep the quality good and stable comparing to the traditional furnaces.

4. Sand Blasting and Grinding

After the green sand iron castings are taken out from sand molds, they would be transferred into next steps for shot blasting or shot-peening to remove the sands and oxide outside of the casting parts. Then the operators will cut off, clean and grind the gating heads, risers, parting lines and sharp edges.

Further processing such as heat treatment, precision machining and surface treatment would be proceeded if the drawings or end-users require.

Aluminium and its alloys could be cast and poured by high pressure die casting, low pressure die casting, gravity casting, sand casting, investment casting and lost foam casting. Usually, the aluminum alloy castings have less weight but complex structural and better surface.

What Aluminium Alloy We Cast by Sand Casting Process:

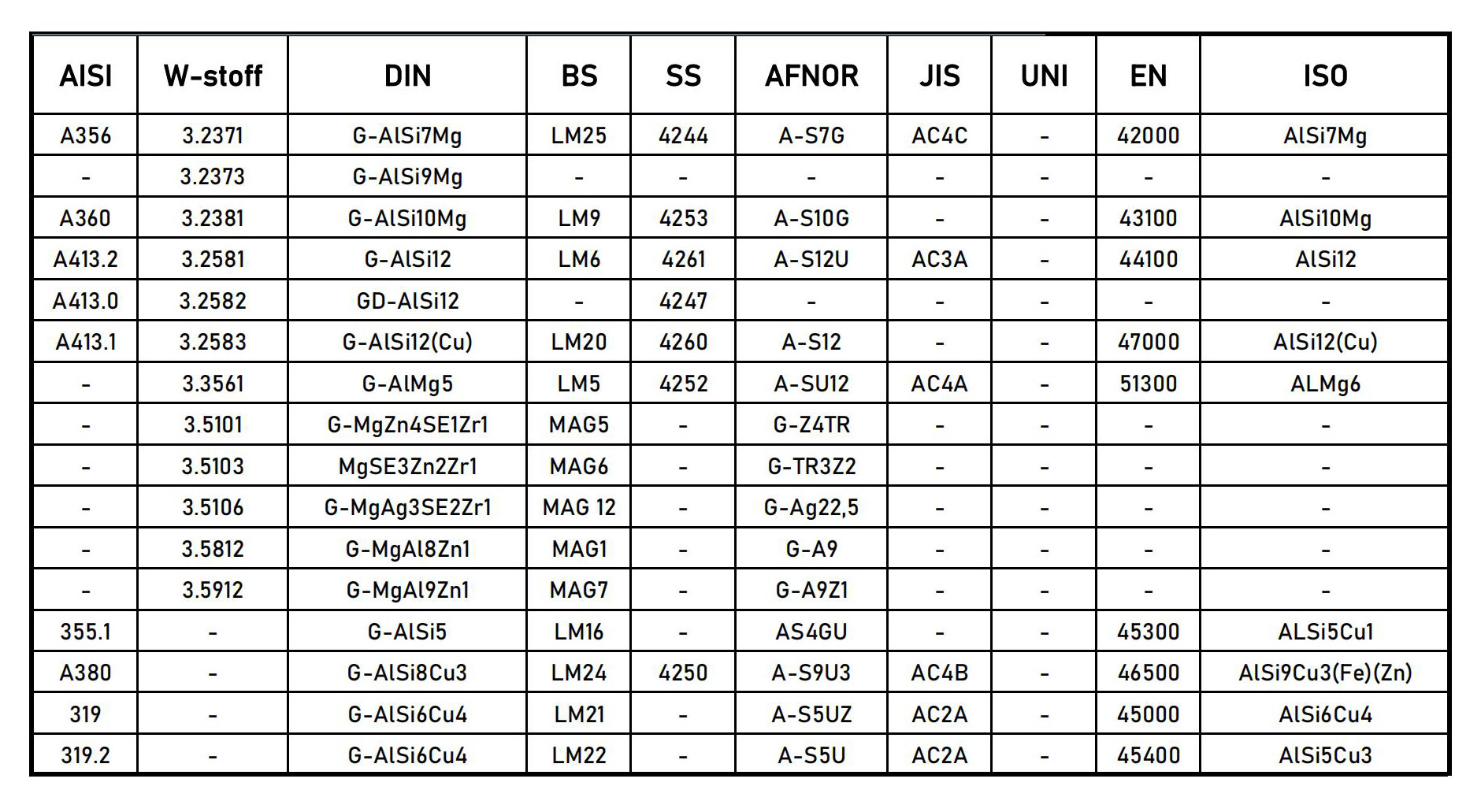

• Cast Aluminium Alloy by China Standard: ZL101, ZL102, ZL104

• Cast Aluminium Alloy by USA Stardard: ASTM A356, ASTM A413, ASTM A360

• Cast Aluminium Alloy by other Starndards: AC3A, AC4A, AC4C, G-AlSi7Mg, G-Al12

| Unified | Aluminium association | Hardness BHN | Ultimate tensile strength, MPa | Yield Strength, MPa | Modulus of elasticity, GPa | Fatigue Strength, MPa |

| A03550 | AA355.0 | 75-105 | 255 | 185 | 70.3 | 69.0 |

| A03600 | AA360.0 | 75.0 | 300 | 170 | 71.0 | 138.0 |

| A03800 | AA380.0 | 80.0 | 317 | 159 | 71.0 | 138.0 |

| A03830 | AA383.0 | 75.0 | 310 | 152 | / | 145.0 |

| A03840 | AA384.0 | 85.0 | 331 | 165 | / | 140.0 |

| A03900 | AA390.0 | 120.0 | 280 | 240 | 81.2 | 140.0 |

| A04130 | AA413.0 | 80.0 | 296 | 145 | 71.0 | 130.0 |

| A04430 | AA443.0 | 30-60 | 145 | 48.3 | 71.0 | / |

| A05180 | AA518.0 | 80.0 | 310 | 193 | 69.0 | 160.0 |

Advantages of Aluminum Alloy Castings:

• The casting performance is similar to that of steel castings, but the relative mechanical properties decrease more significantly as the wall thickness increases

• The wall thickness of castings should not be too large, and other structural features are similar to those of steel castings

• Light weight but complex structural

• The casting costs per kg of aluminium castings are higher than that of iron and steel castings.

• If produced by die casting process, the mold and pattern cost would be much higher than other casting processes. Therefore, die casting aluminium castings would be more suitable for castings of large demanding quantity.

| Typical Chemical Composition of Investment Casting Aluminium Alloy by North American Specifications | ||||||||||||||

| Alloy Grade | Specification | Al | Cu | Si | Zn | Mg | Cr | Fe | Mn | Ti | Ag | Be | Ni | P |

| A356-T6 | AMS 4218 | Bal | 0.20 | 6. 5 – 7. 5 | 0.10 | 0.25-0.45 | - | 0.20 | 0.10 | 0.20 | - | – | - | - |

| A 357 | AMS 4219 | Bal | 0.20 | 6. 5 – 7. 5 | 0.10 | 0.40-.70 | - | 0.20 | 0.10 | 0.04-0.20 | - | 0.04-0.07 | - | - |

| F 357 | AMS 4289 | Bal | 0.20 | 6.5-7.5 | 0.10 | 0.40-.70 | - | 0.10 | 0.10 | 0.04-0.20 | - | 0.002 | - | - |

| E 357 | AMS 4288 | Bal | - | 6.5-7.5 | 0.10 | 0.55-0.60 | - | 0.10 | 0.10 | 0.10-0.20 | - | 0.002 | - | - |

| A201 | AMS 4229 | Bal | 4.0-5.0 | 0.05 | - | 0.15-0.35 | - | 0.10 | 0.20-0.34 | 0.15-0.35 | 0.40-1.0 | - | - | - |

| C355 | AMS 4215 | Bal | 1.0-1.5 | 4.5-5.5 | 0.10 | 0.40-0.60 | - | 0.20 | 0.10max | 0.20 | - | - | - | - |

| A206 | AMS 4235 | Bal | 4.2-5.0 | .05max | 0.05max | 0.20-0.35 | - | 0.10ma | 0.20-0.50 | 0.15-0.30 | - | - | 0.5max | - |

| B206 | Bal | 4.2-5.0 | .05max | 0.05max | 0.15-0.35 | - | 0.10max | 0.20-0.50 | 0 1 0 | - | - | 0.5max | - | |

China Sand Casting Foundry

Product detail pictures:

Related Product Guide:

We've been committed to offering easy,time-saving and money-saving one-stop purchasing support of consumer for Hot Selling for Stainless Steel Sand Casting Foundry - Custom Aluminium Alloy Casting Product – RMC Foundry, The product will supply to all over the world, such as: America , Sevilla , Sri Lanka , With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!

-

Low price for Iron Sand Casting Manufacturer - ...

-

PriceList for Brass Vacuum Casting - Custom Al...

-

Factory wholesale Metal Casting - Custom Inves...

-

Manufactur standard Gray Iron Green Sand Castin...

-

Factory directly supply Steel Casting Manufactu...

-

PriceList for Sand Casting Factory - Malleable...