Factory Outlets Stainless Steel Casting Foundry - Stainless Steel Lost Wax Casting Foundry – RMC Foundry Detail:

Stainless steel castings are mainly cast by lost wax casting because it can reach a high accurate surface and dimension.

Investment casting or lost wax casting is a method of precision casting complex near-net-shape details using replication of wax patterns. Investment casting or lost wax is a metal forming process that typically uses a wax pattern surrounded by a ceramic shell to make a ceramic mold. When the shell dries, the wax is melted away, leaving only the mold. Then the casting component is formed by pouring molten metal into the ceramic mold.

The most widely-used materials of stainless steel mainly include (but not limited to): Stainless Steel: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4404, 1.4301 and other stainless steel grade.

Stainless steel has a minimum chromium content of 10.5%, making it more resistant to corrosive liquid environments and to oxidation. It is highly corrosion resistant and wear resistant, provides excellent machinability, and is well-known for its aesthetic appearance. Stainless steel investment castings are “corrosion-resistant” when used in liquid environments and vapors below 1200°F (650°C) and “heat-resistant” when used above this temperature.

The base alloy elements of any nickel-base or stainless steel investment casting are chromium, nickel, and molybdenum (or “moly”). These three components will determine the casting’s grain structure and mechanical properties and will be instrumental in the casting’s ability to combat heat, wear, and corrosion.

Our lost wax casting foundry can manufacture custom stainless steel investment castings that match your exact design specifications. For parts ranging from tens of grams to tens of kilograms or more, we provide tight tolerances and consistent part to part repeatability.

Commonly, the stainless steel should be cast by the investment precision casting process with the silica sol as the bond. The stainless steel silica sol castings have a very high grade of precision surface and performance.

Due to its unique physical properties, stainless steel castings are popular in a wide range of applications, especially those in harsh environments. Common markets for stainless steel investment castings include oil and gas, fluid power, transportation, hydraulic systems, food industry, hardware and locks, agriculture…etc.

The process is suitable for repeatable production of net shape components from a variety of different metals and high performance alloys. Although generally used for small castings, this process has been used to produce complete aircraft door frames, with steel castings of up to 500 kgs and aluminium castings of up to 50 kgs. Compared to other casting processes such as die casting or sand casting, it can be an expensive process. However, the components that can be produced using investment casting can incorporate intricate contours, and in most cases the components are cast near net shape, so require little or no rework once cast.

Silica sol casting process is the main steel investment casting process of RMC investment casting foundry. We have been developing new technology of adhesive material to achieve much more economical and effective adhesive material to build the slurry shell. It is a overwhelming trend that Silica sol casting process replaces the rough inferior water glass process, especially for stainless steel casting and alloy steel casting. Besides the innovated molding material, the silica sol casting process has also being innovated to much steadier and less heat expanding.

▶ Ferrous and Non-ferrous Materials for Investment Casting, Lost Wax Casting Process:

• Gray Iron: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

• Ductile Iron or Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

• Carbon Steel: AISI 1020 – AISI 1060, C30, C40, C45.

• Steel Alloys: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo…etc on request.

• Stainless Steel: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 and other stainless steel grade.

• Brass, Red Copper, Bronze or other Copper-based alloy metals: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

• Other Materials as per your unique requirements or according to ASTM, SAE, AISI, ACI, DIN, EN, ISO, and GB standards

▶ Capabilities of Investment Casting Foundry

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg – 100 kg

• Annual Capacity: 2,000 tons

• Bond Materials for Shell Building: Silica Sol, Water Glass and their mixtures.

• Tolerances: On Request.

▶ Main Production Procedure

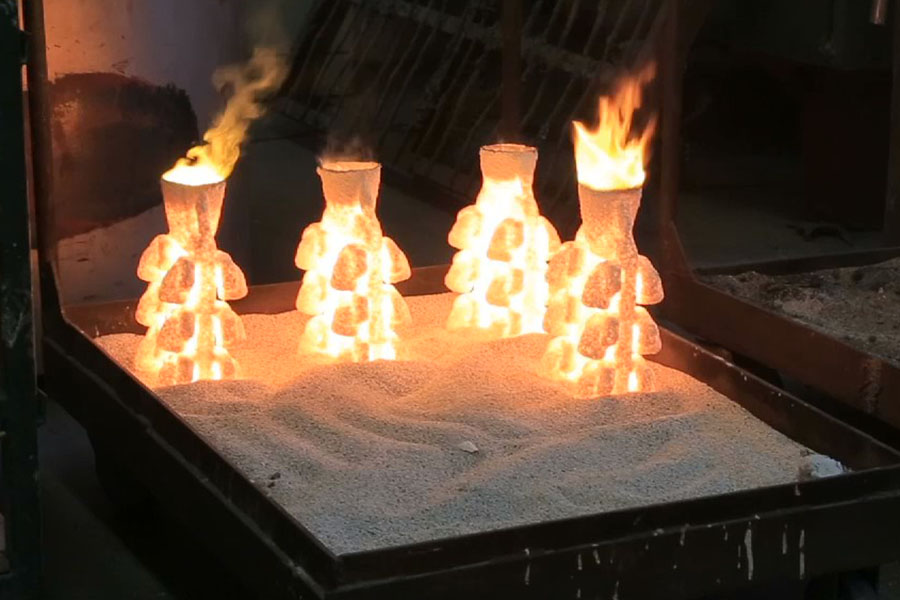

• Patterns & Tooling Design → Metal Die Making → Wax Injection → Slurry Assembly → Shell Building → De-Waxing → Chemical Composition Analysis → Melting & Pouring → Cleaning, Grinding & Shot Blasting → Post Processing or Packing for Shipment

Product detail pictures:

Related Product Guide:

Assume full accountability to satisfy all demands of our consumers; reach ongoing advancements by endorsing the expansion of our purchasers; come to be the final permanent cooperative partner of clients and maximize the interests of clientele for Factory Outlets Stainless Steel Casting Foundry - Stainless Steel Lost Wax Casting Foundry – RMC Foundry, The product will supply to all over the world, such as: Korea , Juventus , Riyadh , They're durable modeling and promoting well all over the world. Under no circumstances disappearing key functions in a brief time, it's a should for you personally of fantastic quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the business make an awesome efforts to expand its international trade, raise its enterprise. rofit and improve its export scale. We are confident that we'll have a vibrant prospect and to be distributed all over the world in the years to come.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.

-

China New Product Casting Factory - Stainless ...

-

Chinese Professional Iron Sand Casting Foundry ...

-

Big Discount Metal Alloy Foundry - Stainless S...

-

Top Suppliers Furan Resin Sand Casting - Low C...

-

China Factory for Brass Sand Casting Foundry - ...

-

New Fashion Design for Iron Casting Foundry - ...