Excellent quality Stainless Steel Investment Casting - Stainless Steel Precision Casting Exhaust Manifold – RMC Foundry Detail:

Stainless Steel Precision Casting with OEM Custom and CNC Machining Services

Our lost wax casting foundry can manufacture custom stainless steel investment castings that match your exact design specifications. For parts ranging from tens of grams to tens of kilograms or more, we provide tight tolerances and consistent part to part repeatability.

▶ Capabilities of Investment Casting Foundry

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg – 100 kg

• Annual Capacity: 2,000 tons

• Bond Materials for Shell Building: Silica Sol, Water Glass and their mixtures.

• Tolerances: On Request.

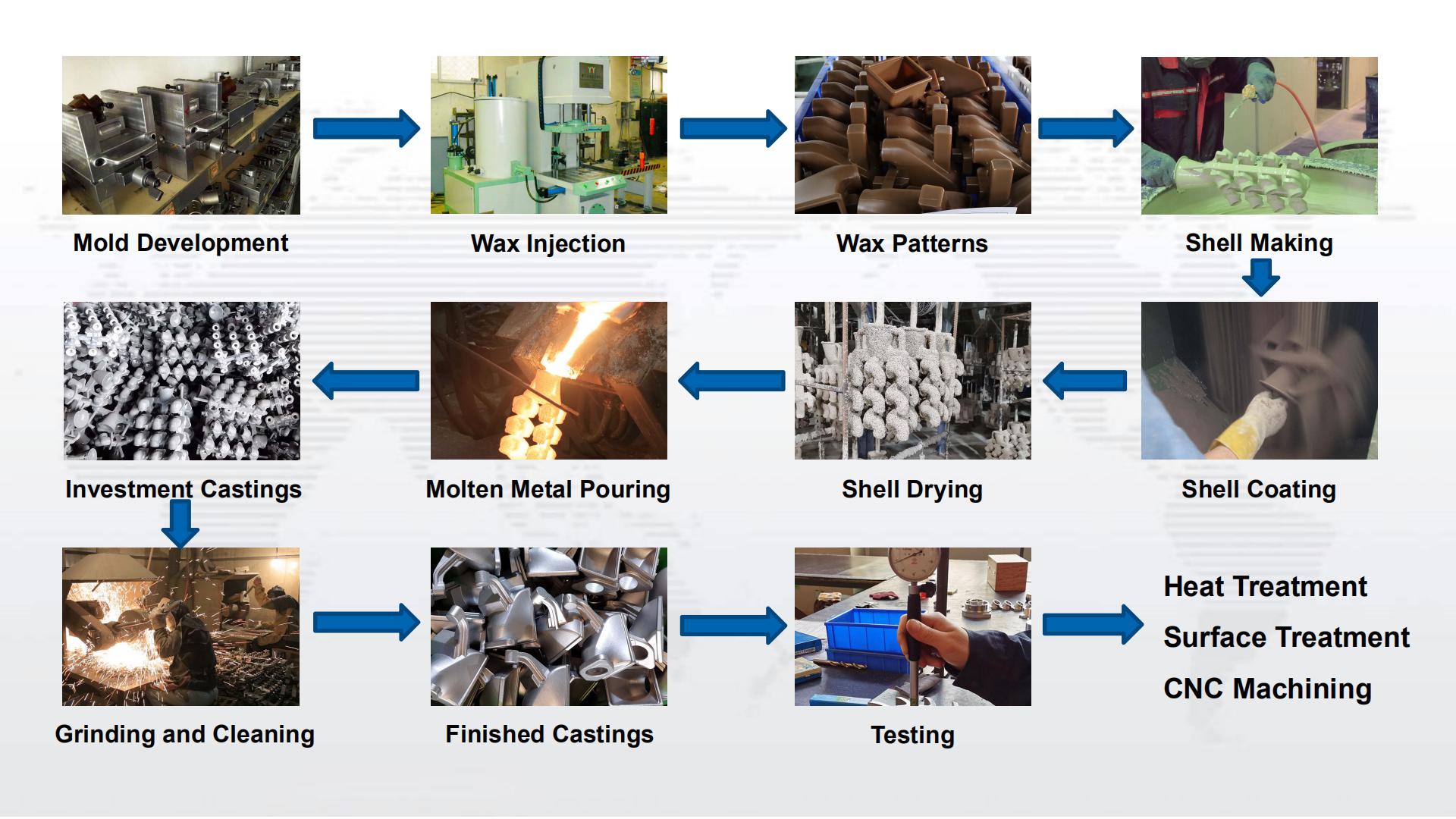

▶ Main Production Procedure

• Patterns & Tooling Design → Metal Die Making → Wax Injection → Slurry Assembly → Shell Building → De-Waxing → Chemical Composition Analysis → Melting & Pouring → Cleaning, Grinding & Shot Blasting → Post Processing or Packing for Shipment

▶ Why You Choose RMC for Custom Lost Wax Casting Parts?

• Full solution from one single supplier ranging customized pattern design to finished castings and secondary process including CNC machining, heat treatment and surface treatment.

• Costdown proposals from our professional engineers based on your unique requirement.

• Short leadtime for prototype, trial casting and any possible technical improvement.

• Bonded Materials: Silica Col, Water Glass and their mixtures.

• Manufacturing flexibility for small orders to mass orders.

• Strong outsourcing manufacturing capabilities.

Product detail pictures:

Related Product Guide:

The corporation upholds the philosophy of "Be No.1 in high quality, be rooted on credit rating and trustworthiness for growth", will continue to serve outdated and new consumers from home and overseas whole-heatedly for Excellent quality Stainless Steel Investment Casting - Stainless Steel Precision Casting Exhaust Manifold – RMC Foundry, The product will supply to all over the world, such as: Czech , Paris , Tajikistan , Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question items they do not understand. We break down people barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.

-

Factory Cheap Hot China Machining Products - B...

-

Massive Selection for Brass Casting Foundry - ...

-

2020 Good Quality Alloy Steel Casting - Alloy ...

-

Cheapest Price Duplex Stainless Steel Sand Cast...

-

Factory wholesale Ductile Iron Sand Casting Com...

-

One of Hottest for Bronze No Bake Casting - CN...