OEM/ODM Design Ductile Iron Sand Casting Foundry – Grey Cast Iron Part with Custom Casting Services – RMC Foundry Detail:

Custom grey cast iron casting parts by sand mold casting and CNC precision machining processes. OEM customized engineering services are also available.

Capabilities of Sand Casting moulded by hand:

• Max Size: 1,500 mm × 1000 mm × 500 mm

• Weight Range: 0.5 kg – 500 kg

• Annual Capacity: 5,000 tons – 6,000 tons

• Tolerances: On Request or Standard (ISO8062-2013 or Chinese Standard GB/T 6414-1999)

• Mold Materials: Green Sand Casting, Shell Mold Sand Casting.

Capabilities of Sand Casting by Automatic Molding Machines:

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg – 500 kg

• Annual Capacity: 8,000 tons – 10,000 tons

• Tolerances: On Request or According to Standard (ISO8062-2013 or Chinese Standard GB/T 6414-1999)

• Mold Materials: Green Sand Casting, Resin Coated Sand Shell Molding Casting.

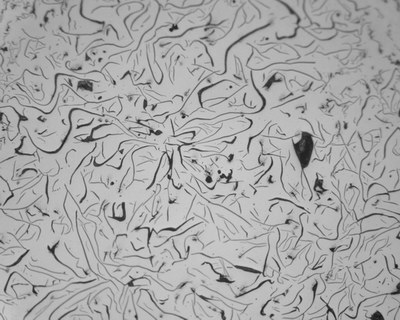

The sand mold casting foundry at RMC is equipped with a complete metallurgical laboratory to determin the chemical and mechanical characteristics of each melt and to analyse the metallurgic condition of the molten metal before pouring. Microsections are examined under the microscope to obtain final information. If possible or needed, we can issure 3.1 Certificate for each delivery part on customers’ demand.

Sand casting products could serve in many industries such as Drums, Gear, Gear Housing, Mining Machinery, Mounting Block, Hydraulic Pressure Pump, Bearing Seat, Support Ring, Idler Wheel, Clamp, Mounting Bracket, Wheel Hub, Wedge Socket, Track Pad For Mining Equipment, Hydraulic Rod Yoke…etc.

| Mechanical Properties of Gray Cast Iron | |||||||

| Item according to DIN EN 1561 | Measure | Unit | EN-GJL-150 | EN-GJL-200 | EN-GJL-250 | EN-GJL-300 | EN-GJL-350 |

| EN-JL 1020 | EN-JL 1030 | EN-JL 1040 | EN-JL 1050 | EN-JL 1060 | |||

| Tensile Strength | Rm | MPA | 150-250 | 200-300 | 250-350 | 300-400 | 350-450 |

| 0.1% Yield Strength | Rp0,1 | MPA | 98-165 | 130-195 | 165-228 | 195-260 | 228-285 |

| Elongation Strength | A | % | 0,3 – 0,8 | 0,3 – 0,8 | 0,3 – 0,8 | 0,3 – 0,8 | 0,3 – 0,8 |

| Compressive Strength | σdB | MPa | 600 | 720 | 840 | 960 | 1080 |

| 0,1% Compressive Strength | σd0,1 | MPa | 195 | 260 | 325 | 390 | 455 |

| Flexural Strength | σbB | MPa | 250 | 290 | 340 | 390 | 490 |

| Schuifspanning | σaB | MPa | 170 | 230 | 290 | 345 | 400 |

| Shear Stress | TtB | MPa | 170 | 230 | 290 | 345 | 400 |

| Modules of elasticity | E | GPa | 78 – 103 | 88 – 113 | 103 – 118 | 108 – 137 | 123 – 143 |

| Poisson number | v | – | 0,26 | 0,26 | 0,26 | 0,26 | 0,26 |

| Brinell hardness | HB | 160 – 190 | 180 – 220 | 190 – 230 | 200 – 240 | 210 – 250 | |

| Ductility | σbW | MPa | 70 | 90 | 120 | 140 | 145 |

| Tension and pressure change | σzdW | MPa | 40 | 50 | 60 | 75 | 85 |

| Breaking Strength | Klc | N/mm3/2 | 320 | 400 | 480 | 560 | 650 |

| Density | g/cm3 | 7,10 | 7,15 | 7,20 | 7,25 | 7,30 | |

Cast iron is an iron-carbon cast alloy with other elements that is made by remelting pig iron, scrap, and other additions. For differentia- tion from steel and cast steel, cast iron is defined as a cast alloy with a carbon content (min 2.03%) that ensures the solidification of the final phase with a eutectic transformation. Depending on chemical specifications, cast irons can be non- alloyed or alloyed. The range of alloyed irons is much wider, and they contain either higher amounts of common components, such as silicon and manganese, or special additions, such as nickel, chromium, aluminum, molybdenum, tungsten, copper, vana- dium, titanium, plus others. Generally speaking, the cast iron could be divided into gray iron, ducitle iron (nodular iron), white cast iron, compacted graphite iron and malleable cast iron.

Product detail pictures:

Related Product Guide:

Adhering to your principle of "quality, assistance, performance and growth", we have now gained trusts and praises from domestic and international customer for OEM/ODM Design Ductile Iron Sand Casting Foundry – Grey Cast Iron Part with Custom Casting Services – RMC Foundry, The product will supply to all over the world, such as: UK , UK , Brazil , Our items have national accreditation requirements for qualified, high quality goods, affordable value, was welcomed by people today all over the world. Our products will continue to enhance within the order and look forward to cooperation with you, Should really any of these products and solutions be of curiosity to you, be sure to letus know. We are likely to be content to offer you a quotation up on receipt of your detailed needs.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.

-

New Arrival China China Machining Manufacturer ...

-

2020 wholesale price Ductile Iron Sand Casting ...

-

Excellent quality Precision Casting Parts - CN...

-

2020 Good Quality Stainless Steel Investment Ca...

-

Factory Supply Sand Casting Manufacturer - Duc...

-

Low price for Aluminium Investment Casting - B...