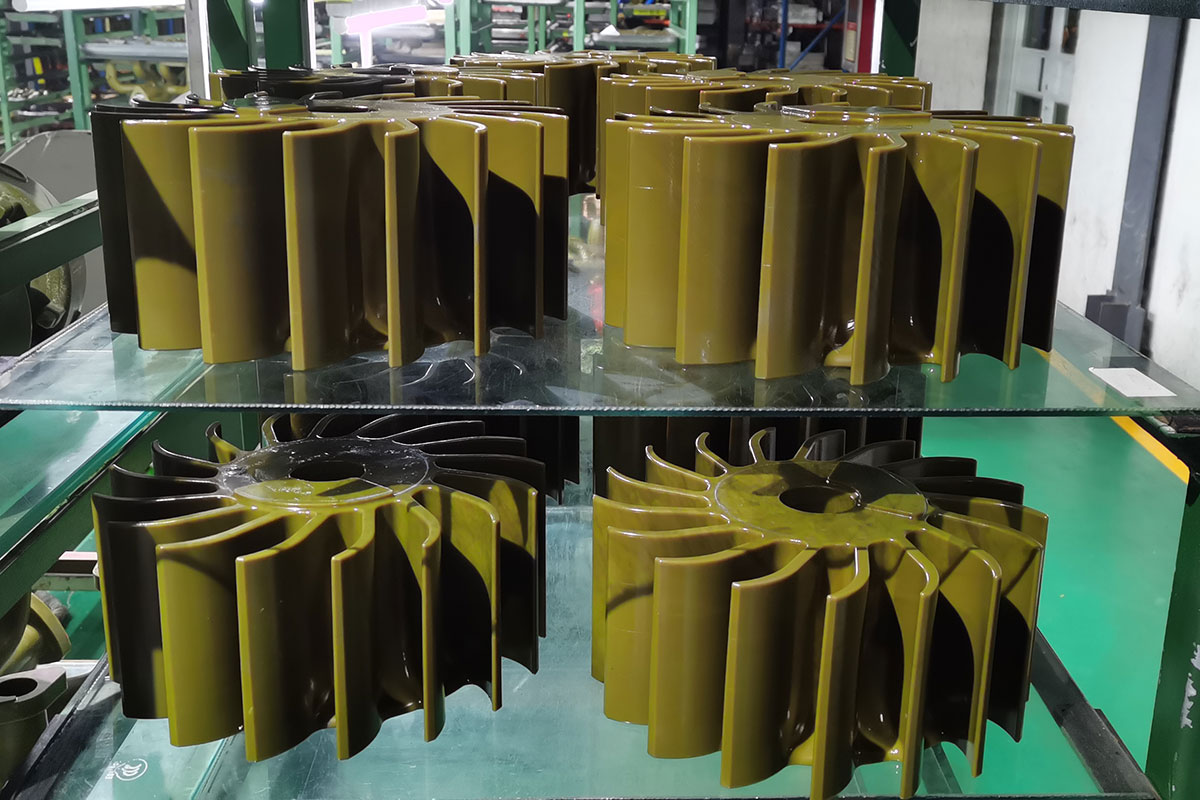

High Quality Steel Investment Casting - Custom Stainless Steel Impeller by Investment Casting – RMC Foundry Detail:

China OEM custom stainless steel impeller by lost wax investment casting process.

The base alloy elements of any nickel-base or stainless steel investment casting are chromium, nickel, and molybdenum (or “moly”). These three components will determine the casting’s grain structure and mechanical properties and will be instrumental in the casting’s ability to combat heat, wear, and corrosion.

Stainless steel has a minimum chromium content of 10.5%, making it more resistant to corrosive liquid environments and to oxidation. However, this is not absolute. Stainless steel investment castings are “corrosion-resistant” when used in liquid environments and vapors below 1200°F (650°C) and “heat-resistant” when used above this temperature.

Advantages of Investment Casting Components:

- Excellent and smooth surface finish

- Tight dimensional tolerances.

- Complex and intricate shapes with design flexibility

- Capability to cast thin walls therefore a lighter casting component

- Wide selection of cast metals and alloys (ferrous and non-ferrous)

- Draft is not required in the molds design.

- Reduce the need for secondary machining.

- Low material waste.

| Materials for Investment Casting Process at RMC Foundry | |||

| Category | China Grade | US Grade | Germany Grade |

| Ferritic Stainless Steel | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Martensitic Stainless Steel | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Austenitic stainless steel | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 |

302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4406, 1.4408, 1.4409, 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Precipitation Hardening Stainless Steel | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex Stainless Steel | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 |

1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| High Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Tool Steel | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Heat Resistant Steel | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo |

309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Nickle-base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35-1, INCOLOY600, INCOLOY625 |

2.4815, 2.4879, 2.4680 | |

| Aluminum Alloy |

ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Copper Alloy | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 |

C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Cobalt-base Alloy | UMC50, 670, Grade 31 | 2.4778 | |

| INVESTMENT CASTING TOLERANCES | |||

| Inches | Millimeters | ||

| Dimension | Tolerance | Dimension | Tolerance |

| Up to 0.500 | ±.004″ | Up to 12.0 | ± 0.10mm |

| 0.500 to 1.000” | ±.006″ | 12.0 to 25.0 | ± 0.15mm |

| 1.000 to 1.500” | ±.008″ | 25.0 to 37.0 | ± 0.20mm |

| 1.500 to 2.000” | ±.010″ | 37.0 to 50.0 | ± 0.25mm |

| 2.000 to 2.500” | ±.012″ | 50.0 to 62.0 | ± 0.30mm |

| 2.500 to 3.500” | ±.014″ | 62.0 to 87.0 | ± 0.35mm |

| 3.500 to 5.000” | ±.017″ | 87.0 to 125.0 | ± 0.40mm |

| 5.000 to 7.500” | ±.020″ | 125.0 to190.0 | ± 0.50mm |

| 7.500 to 10.000” | ±.022″ | 190.0 to 250.0 | ± 0.57mm |

| 10.000 to 12.500” | ±.025″ | 250.0 to 312.0 | ± 0.60mm |

| 12.500 to 15.000 | ±.028″ | 312.0 to 375.0 | ± 0.70mm |

Stainless Steel Castings by Investment Casting

Product detail pictures:

Related Product Guide:

Gaining customer satisfaction is our company's aim forever. We will make great efforts to develop new and top-quality products, meet your special requirements and provide you with pre-sale, on-sale and after-sale services for High Quality Steel Investment Casting - Custom Stainless Steel Impeller by Investment Casting – RMC Foundry, The product will supply to all over the world, such as: Argentina , Armenia , Myanmar , We supply skilled service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound items with good logistics service and economical cost. Depending on this, our products and solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ??customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!