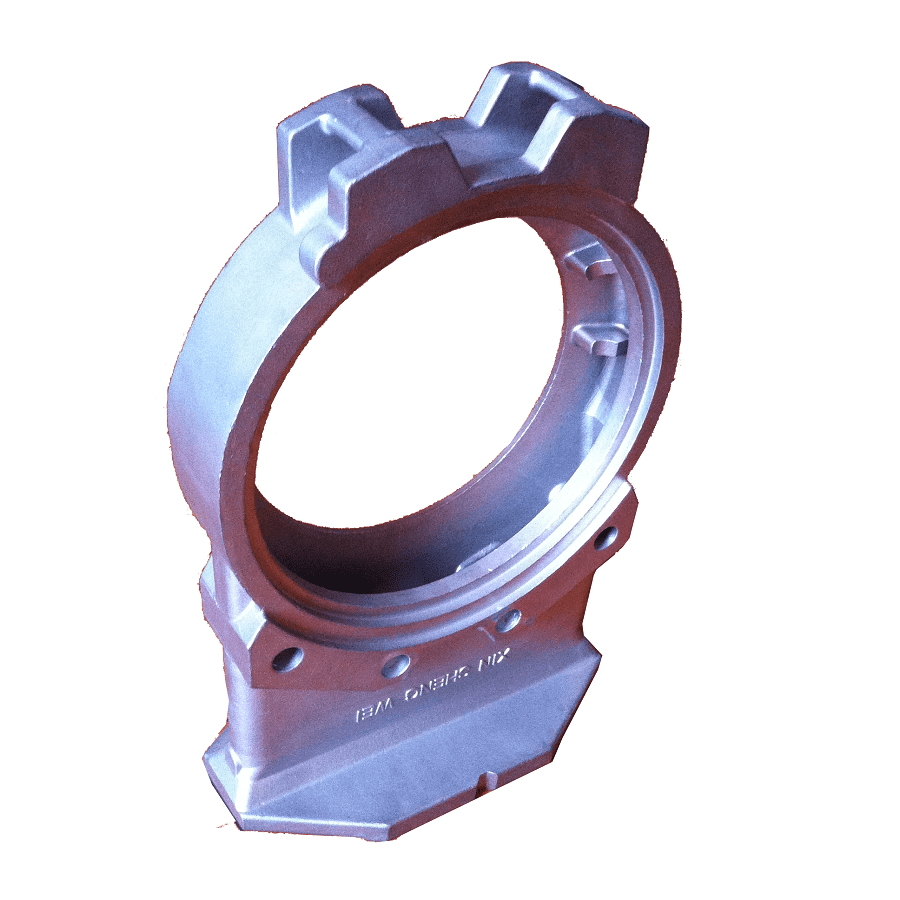

Chinese wholesale Steel Vacuum Casting Supplier - Alloy Steel Casting Draft Gear Housing – RMC Foundry Detail:

Vacuum casting steel draft gear housing for freight cars for Russian markets with CNC machining and custom tairlor-made services. Cast alloy steel v process castings mean the casting parts produced by vacuum casting process with materials of cast alloy steel.

Vacuum moulding casting, is also called negative pressure molding method, vacuum sealing molding method, or V process for short. This is a relatively new type of physical modeling method. The negative pressure molding method uses the pressure difference between the inside and outside of the mold to fasten the dry and loose sand particles together to obtain a mold with a certain desired shape and a certain strength.

Advantages of Vacuum Casting Process

1) The vacuum castings have high dimensional accuracy, clear outline and smooth surface.

Because the surface of the model is covered with plastic film, there is no need to vibrate or knock when pull the mold. The suction and negative pressure make the molding sand compact, and the hardness of the sand mold is high and uniform. Under the heat of molten metal, the cavity is not easy to deform. Moreover, the existence of negative pressure is conducive to the full filling of molten metal into the model. The surface roughness of V process castings can reach Ra = 25 ~ 2.5μm. The dimensional tolerance level of castings can reach CT5 ~ CT7. The appearance quality of negative pressure castings is good, and the internal quality is reliable.

2) There are no binders, water and additives in the molding sand, which makes the sand processing simple.

3) It is simple to clean the vacuum castings. Less harmful gases are generated during the casting process.

4) The vacuum castings could be used at a wide range of industries. It can be used for single-piece small batch production as well as mass production, especially large and medium-sized castings and thin-walled castings are more suitable for vacuum casting.

| Lost Foam Casting vs Vacuum Casting | ||

| Item | Lost Foam Casting | Vacuum Casting |

| Suitable Castings | Small and medium-sized castings with complex cavities, such as engine block, engine cover | Medium and large castings with few or no cavities, such as cast iron counterweights, cast steel axle housings |

| Patterns and Plates | Foam patterns made by moldings | Template with suction box |

| Sand Box | Bottom or five sides exhaust | Four sides exhaust or with exhaust pipe |

| Plastic Film | The top cover is sealed by plastic films | All sides of both halves of sand box are sealed by plastic films |

| Coating Materials | Water-based paint with thick coating | Alcohol-based paint with thin coating |

| Molding Sand | Coarse dry sand | Fine dry sand |

| Vibration Molding | 3 D Vibration | Vertical or Horizontal Vibration |

| Pouring | Negative Pouring | Negative Pouring |

| Sand Process | Relieve negative pressure, turn over the box to drop sand, and the sand is then reused | Relieve negative pressure, then the dry sand falls into the screen, and the sand is recycled |

▶ Vacuum Casting Materials:

• Carbon Steel: Low Carbon Steel, Medium Carbon Steel and High Carbon Steel from AISI 1020 to AISI 1060.

• Cast Steel Alloys: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo…etc on request.

• Stainless Steel: AISI 304, AISI 304L, AISI 316, AISI 316L and other stainless steel grade.

• Brass & Copper.

• Other Materials and Standards on request

▶ V Process Casting Capacities:

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg – 100 kg

• Annual Capacity: 2,000 tons

• Tolerances: On Request.

▶ Inspecting V-Process Casting Components:

• Spectrographic and manual quantitative analysis

• Metallographic analysis

• Brinell, Rockwell and Vickers hardness inspection

• Mechanical property analysis

• Low and normal temperature impact testing

• Cleanliness inspection

• UT, MT and RT inspection

▶ Vacuum Casting Procedures:

• The pattern is covered tightly by a thin sheet of plastic.

• A flask is placed over the coated pattern and is filled with dry sand without bind.

• The second flak is then placed on top of the sand, and a vacuum draws the sand so that the pattern can be tight and withdrawn. Both halves of the mold are made and assembled in this way.

• During pouring, the mold remains under a vacuum but the casting cavity does not.

• When the metal has solidified, the vacuum is turned off and the sand falls away, releasing the casting.

• Vacuum molding produces casting with high-quality detail and dimensional accuracy.

• It is especially well suited for large, relatively flat castings.

▶ Post-Casting Process

• Deburring & Cleaning

• Shot Blasting / Sand Peening

• Heat Treatment: Normalization, Quench, Tempering, Carburization, Nitriding

• Surface Treatment: Passivation, Andonizing, Electroplating, Hot Zinc Plating, Zinc Plating, Nickel Plating, Polishing, Electro-Polishing, Painting, GeoMet, Zintec.

• Machining: Turning, Milling, Lathing, Drilling, Honing, Grinding.

▶ Why You Choose RMC for V (Vacuum) Process Casting Components?

• Easy recovery of the sand because the binders are not used

• Sand does not require mechanical reconditioning.

• Good air permeability because there is no water is mixed with sand, therefore less casting defects.

• More suitable for large scale castings

• Cost effective, especially for large castings.

Product detail pictures:

Related Product Guide:

Our primary objective is always to offer our clients a serious and responsible small business relationship, offering personalized attention to all of them for Chinese wholesale Steel Vacuum Casting Supplier - Alloy Steel Casting Draft Gear Housing – RMC Foundry, The product will supply to all over the world, such as: Suriname , Afghanistan , Ghana , Now, with the development of internet, and the trend of internationalization, we've got decided to extend business to overseas market. With the propose of bringing more profits to oversea customers by providing directly abroad. So we have changed our mind, from home to abroad, hope to give our customers more profit, and looking forward to more chance to make business.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.

-

Factory Price Alloy Steel Casting Foundry - Al...

-

Wholesale Dealers of Super Duplex Stainless Ste...

-

Hot Sale for Brass Green Sand Casting - Gray I...

-

Special Price for Aluminium Precision Casting -...

-

100% Original Aluminium Alloy Investment Castin...

-

New Arrival China Gray Iron Shell Mold Casting ...