China Cheap price Shell Mold Casting Parts - Nodular Cast Iron Shell Casting Product – RMC Foundry Detail:

China OEM custom ductile cast iron shell mold casting products.

Shell molding casting process is also called pre-coated resin sand casting process, hot shell molding castings or core casting process. The main molding material is the pre-coated phenolic resin sand, which is more expensive than green sand and furan resin sand. Moreover, this sand can not be recycle used.

Furan resin self-hardening sand casting process (nobake process) uses the furan resin coated sand to form the casting mold. After mixing the original sand (or reclaimed sand), liquid furan resin and liquid catalyst evenly, and filling them into the core box (or sand box), and then tighten it to harden into a mold or mold in the core box (or sand box) at room temperature. Then the casting mould or casting core were formed, which is called self-hardening cold-core box molding (core), or self-hardening method (core).

Because the mold is formed at room temperature and no need to heat, the self-hardening sand casting is also called no-bake casting process. The self-hardening method can be divided into acid-catalyzed furan resin and phenolic resin sand self-hardening method, urethane resin sand self-hardening method and phenolic monoester self-hardening method.

As a self-hardening cold box binder sand, furan resin sand is the earliest and currently most widely used synthetic binder sand in Chinese foundry. The amount of resin added in molding sand is generally 0.7% to 1.0%, and the amount of added resin in core sand is generally 0.9% to 1.1%. The content of free aldehyde in furan resin is below 0.3%, and some factories have dropped to below 0.1%. In the foundries in China, the furan resin self-hardening sand has reached the international level regardless of the production process and the surface quality of the castings.

The Advantages of Furan Resin Coated Sand Self-hardening Molding Casting:

1) Improve the dimensional accuracy of castings and the surface roughness.

2) The hardening of the mold (core) sand does not require drying, which can save energy, and inexpensive wood or plastic core boxes and templates can also be used.

3) Self-hardnening molding sand is easy to compact and collapse, easy to clean up castings, and old sand can be recycled and reused, which greatly reduces the labor intensity of core making, modeling, sand falling, cleaning and other links, and it is easy to realize mechanization or automation.

4) The mass fraction of resin in sand is only 0.8%~2.0%, and the comprehensive cost of raw materials is low.

Because the self-hardening method has many of the above-mentioned unique advantages, the self-hardening method is not only used for core making, but also used for casting moulding. It is especially suitable for single piece and small batch production, and can produce cast iron, cast steel and non-ferrous alloy castings. Some Chinese foundries have completely replaced clay dry sand molds, cement sand molds, and partially replaced water glass sand molds.

Post-Machining Services

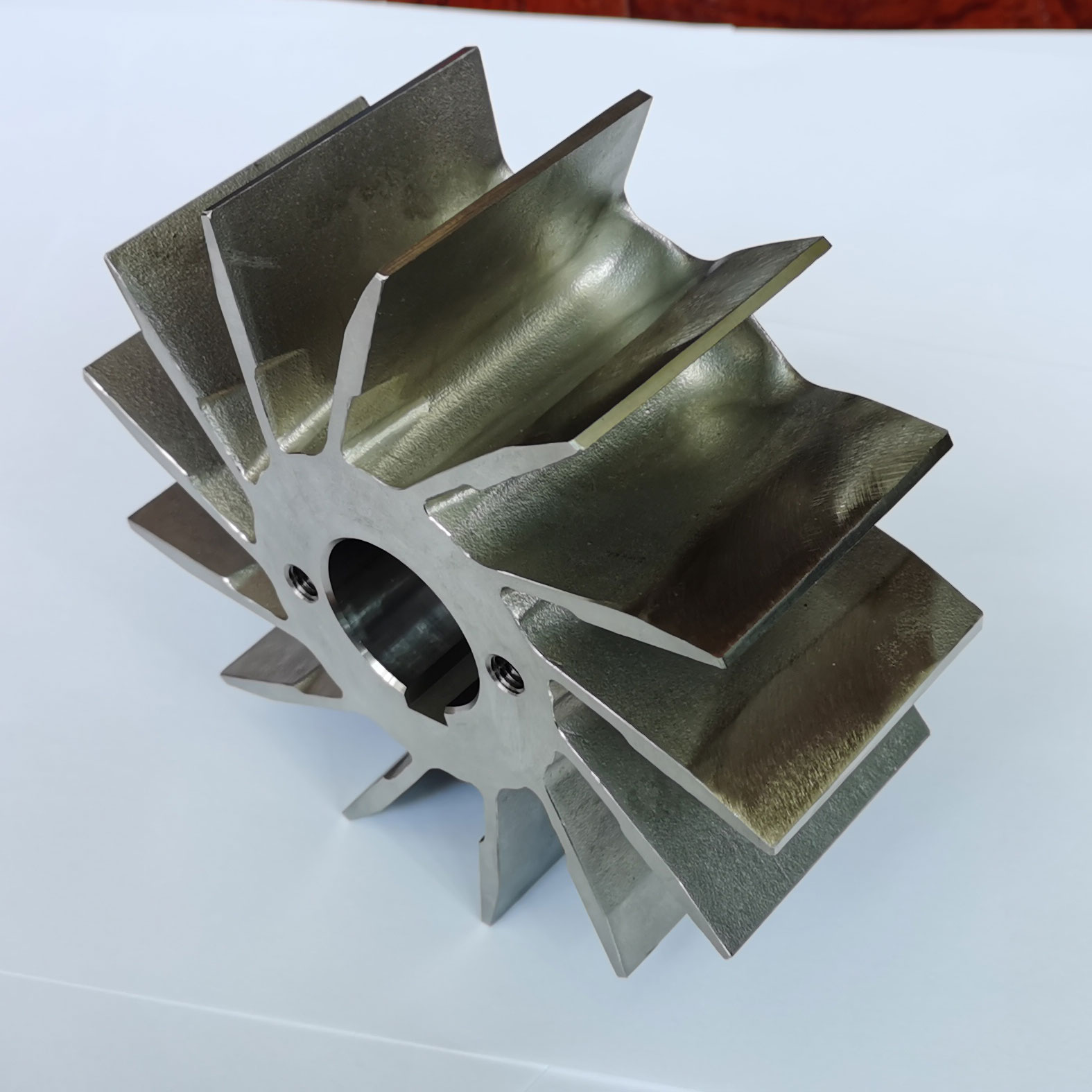

Ductile Iron Machining Products

Product detail pictures:

Related Product Guide:

Together with the "Client-Oriented" enterprise philosophy, a arduous good quality control technique, sophisticated producing equipment and a sturdy R&D staff, we generally offer superior quality merchandise, superb solutions and aggressive rates for China Cheap price Shell Mold Casting Parts - Nodular Cast Iron Shell Casting Product – RMC Foundry, The product will supply to all over the world, such as: Myanmar , Juventus , Amman, Our company mission is that providing high quality and beautiful products with reasonable price and strive to gain 100% good reputation from our clients. We believe Profession achieves excellence! We welcome you to cooperate with us and grow up together.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!

-

High reputation Alloy Steel Lost Wax Casting Pr...

-

Factory directly Steel Precision Casting Suppli...

-

Factory source Carbon Steel No Bake Casting - ...

-

Manufacturing Companies for Alloy Steel No Bake...

-

Reasonable price for Stainless Steel Lost Wax C...

-

Factory For Stainless Steel Lost Wax Casting Su...