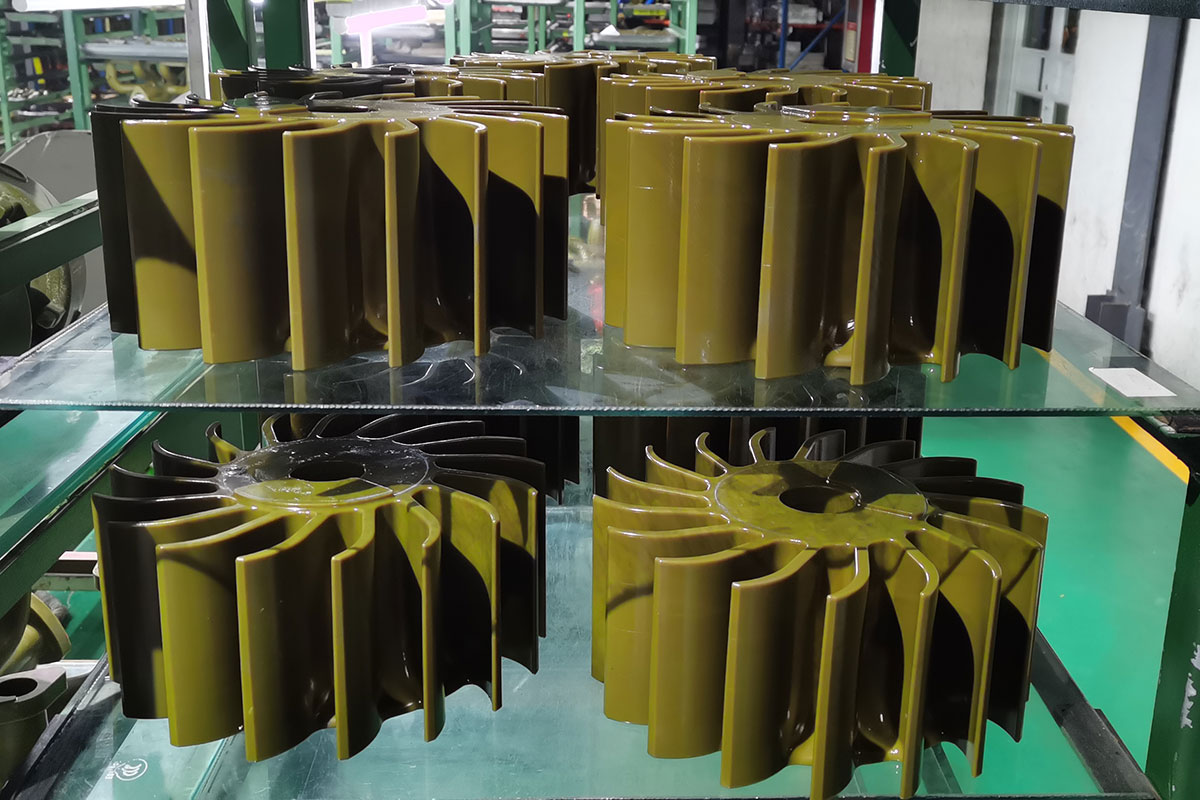

Best quality Steel Investment Casting Supplier - Custom Stainless Steel Impeller by Investment Casting – RMC Foundry Detail:

China OEM custom stainless steel impeller by lost wax investment casting process.

The base alloy elements of any nickel-base or stainless steel investment casting are chromium, nickel, and molybdenum (or “moly”). These three components will determine the casting’s grain structure and mechanical properties and will be instrumental in the casting’s ability to combat heat, wear, and corrosion.

Stainless steel has a minimum chromium content of 10.5%, making it more resistant to corrosive liquid environments and to oxidation. However, this is not absolute. Stainless steel investment castings are “corrosion-resistant” when used in liquid environments and vapors below 1200°F (650°C) and “heat-resistant” when used above this temperature.

Advantages of Investment Casting Components:

- Excellent and smooth surface finish

- Tight dimensional tolerances.

- Complex and intricate shapes with design flexibility

- Capability to cast thin walls therefore a lighter casting component

- Wide selection of cast metals and alloys (ferrous and non-ferrous)

- Draft is not required in the molds design.

- Reduce the need for secondary machining.

- Low material waste.

| Materials for Investment Casting Process at RMC Foundry | |||

| Category | China Grade | US Grade | Germany Grade |

| Ferritic Stainless Steel | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Martensitic Stainless Steel | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Austenitic stainless steel | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 |

302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4406, 1.4408, 1.4409, 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Precipitation Hardening Stainless Steel | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex Stainless Steel | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 |

1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| High Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Tool Steel | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Heat Resistant Steel | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo |

309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Nickle-base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35-1, INCOLOY600, INCOLOY625 |

2.4815, 2.4879, 2.4680 | |

| Aluminum Alloy |

ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Copper Alloy | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 |

C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Cobalt-base Alloy | UMC50, 670, Grade 31 | 2.4778 | |

| INVESTMENT CASTING TOLERANCES | |||

| Inches | Millimeters | ||

| Dimension | Tolerance | Dimension | Tolerance |

| Up to 0.500 | ±.004″ | Up to 12.0 | ± 0.10mm |

| 0.500 to 1.000” | ±.006″ | 12.0 to 25.0 | ± 0.15mm |

| 1.000 to 1.500” | ±.008″ | 25.0 to 37.0 | ± 0.20mm |

| 1.500 to 2.000” | ±.010″ | 37.0 to 50.0 | ± 0.25mm |

| 2.000 to 2.500” | ±.012″ | 50.0 to 62.0 | ± 0.30mm |

| 2.500 to 3.500” | ±.014″ | 62.0 to 87.0 | ± 0.35mm |

| 3.500 to 5.000” | ±.017″ | 87.0 to 125.0 | ± 0.40mm |

| 5.000 to 7.500” | ±.020″ | 125.0 to190.0 | ± 0.50mm |

| 7.500 to 10.000” | ±.022″ | 190.0 to 250.0 | ± 0.57mm |

| 10.000 to 12.500” | ±.025″ | 250.0 to 312.0 | ± 0.60mm |

| 12.500 to 15.000 | ±.028″ | 312.0 to 375.0 | ± 0.70mm |

Stainless Steel Castings by Investment Casting

Product detail pictures:

Related Product Guide:

Good quality To start with,and Purchaser Supreme is our guideline to offer the top service to our customers.Presently, we've been seeking our best to be amongst the top exporters inside our industry to fulfill consumers extra need to have for Best quality Steel Investment Casting Supplier - Custom Stainless Steel Impeller by Investment Casting – RMC Foundry, The product will supply to all over the world, such as: New Zealand , Georgia , Uzbekistan , As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products and solutions we supply, effective and satisfying consultation service is supplied by our professional after-sale service group. Solution lists and thorough parameters and any other info weil be sent for you timely for the inquiries. So make sure you get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we have been going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.

-

Cheap price Nodular Iron No Bake Casting - Los...

-

Factory Outlets Zinc Alloy Sand Casting - Nodu...

-

Wholesale Dealers of Super Duplex Stainless Ste...

-

High reputation Alloy Steel Lost Wax Casting Pr...

-

Reasonable price Alloy Steel Casting Parts - C...

-

Special Price for Aluminium Precision Casting -...