100% Original Factory Gray Iron Casting Manufacturer - Stainless Steel CNC Machined Pump Housing – RMC Foundry Detail:

China CNC machining services provider to have the stainless steel machined as per your drawings and requirements, used for pump housing and body.

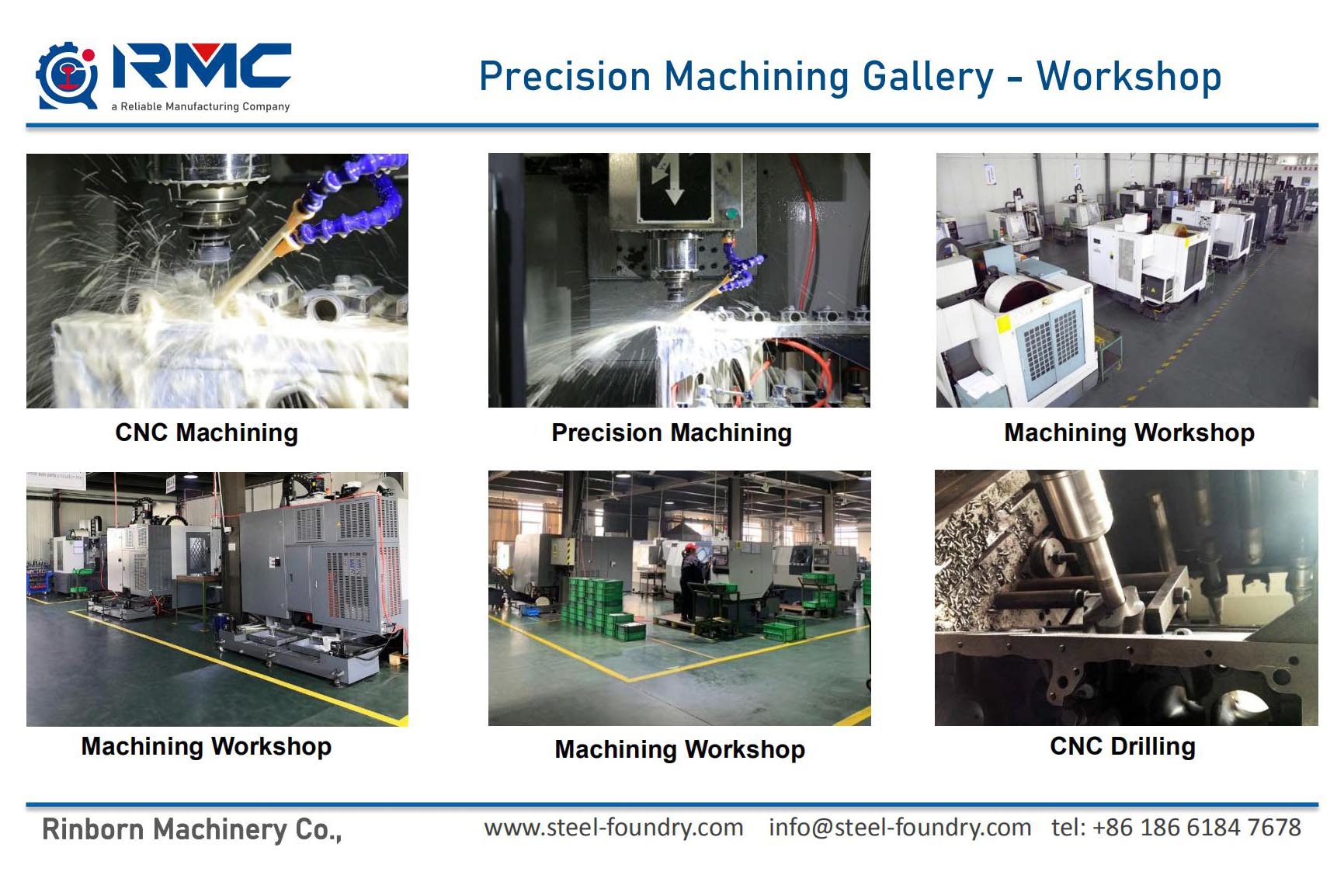

CNC machining refers to the machining process proceed by Computerized Numberical Control (CNC for short). It is aided by the CNC to reach a high and steady accuracy with less labor cost. Machining is any of various processes in which a piece of raw material is cut into a desired final shape and size by a controlled material-removal process. The processes that have this common theme, controlled material removal, are today collectively known as subtractive manufacturing, in distinction from processes of controlled material addition, which are known as additive manufacturing.

Exactly what the “controlled” part of the definition implies can vary, but it almost always implies the use of machine tools (in addition to just power tools and hand tools). This is a process used to manufacture many metal products, but it can also be used on materials such as wood, plastic, ceramic, and composites. The CNC machining covers many different processes such as milling, turning, lathing, drilling, honing, grinding…etc.

| CNC Precision Machining Capabilities | ||||

| Facilities | Quantity | Size Range | Annual Capacity | General Accuracy |

| Vertical Machining Center (VMC) | 48 sets | 1500mm × 1000mm × 800mm | 6000 tonn or 300000 pieces | ±0.005 |

| Horizontal Machining Center (VMC) | 12 sets | 1200mm × 800mm × 600mm | 2000 tons or 100000 pieces | ±0.005 |

| CNC Machine | 60 sets | Max turning dia. φ600mm | 5000 tons or 600000 pieces | |

| Excutive Standard of Casting Tolerance: ISO 8062 2013, ISO 2768, GOST 26645 (Russia) or GBT 6414 (China). | ||||

The machining center is developed from the CNC milling machine. The biggest difference from the CNC milling machine is that the machining center has the ability to automatically exchange machining tools. By installing tools for different purposes on the tool magazine, the machining tools on the spindle can be changed by the automatic tool changer in one clamping to realize multiple machining features.

The CNC machining center is a high-efficiency automated machine tool that is composed of mechanical equipment and a CNC system and is suitable for processing complex parts. The CNC machining center is currently one of the most widely used CNC machine tools in the world with strong comprehensive processing ability. It can complete more processing content after the workpiece is clamped at one time. The processing accuracy is high. For batch workpieces with medium processing difficulty, its efficiency is 5-10 times that of ordinary equipment, especially it can complete Many processings that cannot be completed by ordinary equipment are more suitable for single-piece processing with more complex shapes and high precision requirements or for small and medium batch production of multiple varieties. It concentrates the functions of milling, boring, drilling, tapping and cutting threads on one device, so that it has a variety of technological means.

Machining centers are classified into horizontal and vertical machining centers according to their spatial position during spindle machining. Classified according to process use: boring and milling machining center, compound machining center. According to the special classification of functions, there are: single workbench, double workbench and multi-workbench machining center. Machining centers with single-axis, dual-axis, three-axis, four-axis, five-axis and interchangeable headstocks, etc.

CNC machining is the kind of precision machining by CNC machines such as advanced machining centers which have top end 5 axis machining center, 4 axis double platform machining center, or CNC turning lathes which can also be developed to CNC turning center having capability of changing more than 15 cutters within one holding shift; CNC milling machine and CNC drilling and tapping centers.Precision machining of steel casting is different from machining of steel profile. Precision casting has already achieve quite exact shape of what is desired, thus it saves lots of machining compared with machining from steel profile directly. Also because of this reason, we usually have to consider machining surface and proper machining allowance before casting. Our regular procure is to work out raw casting drawing along with machining drawing to specify machining area and machining allowance on the drawing.

RMC investment casting foundry has equipped with 4 axis machining centers, 15 sets of CNC turning lathes and 3 sets of cnc milling machines, along with assistant common versatile turning, milling, tapping, drilling and grinding machines, we have the capability of machining nearly all kinds of steel castings.

| Equivalent Grade of Cast Alloy Steel from Different Markets | |||||||||

| GROUPS | AISI | W-stoff | DIN | BS | SS | AFNOR | U.N.E. / I.H.A. | JIS | UNI |

| Low Alloy Steel | 9255 | 1.0904 | 55 Si 7 | 250 A 53 | 2090 | 55 S 7 | 56Si7 | - | 5SSi8 |

| 1335 | 1.1167 | 36 Mn 5 | 150 M 36 | 2120 | 40 M 5 | 36Mn5 | SMn 438(H) | - | |

| 1330 | 1.1170 | 28 Mn 6 | 150 M 28 | - | 20 M 5 | - | SCMn1 | C28MN | |

| P4 | 1.2341 | X6 CrMo 4 | - | - | - | - | - | - | |

| 52100 | 1.3505 | 100 Cr 6 | 534 A 99 | 2258 | 100 C 6 | F.131 | SUJ 2 | 100Cr6 | |

| A204A | 1.5415 | 15 Mo 3 | 1501 240 | 2912 | 15 D 3 | 16 Mo3 | STBA 12 | 16Mo3 KW | |

| 8620 | 1.6523 | 21 NiCrMo 2 | 805 M 20 | 2506 | 20 NCD 2 | F.1522 | SNCM 220(H) | 20NiCrMo2 | |

| 8740 | 1.6546 | 40NiCrMo22 | 311-Type 7 | - | 40 NCD 2 | F.129 | SNCM 240 | 40NiCrMo2(KB) | |

| - | 1.6587 | 17CrNiMo6 | 820 A 16 | - | 18 NCD 6 | 14NiCrMo13 | - | - | |

| 5132 | 1.7033 | 34 Cr 4 | 530 A 32 | - | 32 C 4 | 35Cr4 | SCr430(H) | 34Cr4(KB) | |

| 5140 | 1.7035 | 41 Cr 4 | 530 A 40 | - | 42 C 2 | 42 Cr 4 | SCr 440 (H) | 40Cr4 | |

| 5140 | 1.7035 | 41 Cr 4 | 530 A 40 | - | 42 C 2 | 42 Cr 4 | SCr 440 (H) | 41Cr4 KB | |

| 5140 | 1.7045 | 42 Cr 4 | 530 A 40 | 2245 | 42 C 4 TS | F.1207 | SCr 440 | - | |

| 5115 | 1.7131 | 16 MnCr 5 | (527 M 20) | 2511 | 16 MC 5 | F.1516 | - | 16MnCr5 | |

| 5155 | 1.7176 | 55 Cr 3 | 527 A 60 | 2253 | 55 C 3 | - | SUP 9(A) | 55Cr3 | |

| 4130 | 1.7218 | 25 CrMo 4 | 1717CDS 110 | 2225 | 25 CD 4 | F.1251/55Cr3 | SCM 420 / SCM430 | 25CrMo4(KB) | |

| 4135 (4137) | 1.7220 | 35 CrMo 4 | 708 A 37 | 2234 | 35 CD 4 | 34 CrMo 4 | SCM 432 | 34CrMo4KB | |

| 4142 | 1.7223 | 41 CrMo 4 | 708 M 40 | 2244 | 42 CD 4 TS | 42 CrMo 4 | SCM 440 | 41 CrMo 4 | |

| 4140 | 1.7225 | 42 CrMo 4 | 708 M 40 | 2244 | 40 CD 4 | F.1252 | SCM 440 | 40CrMo4 | |

| 4137 | 1.7225 | 42 CrMo 4 | 708 M 40 | 2244 | 42 CD 4 | F.1252 | SCM 440 | 42CrMo4 | |

| A387 12-2 | 1.7337 | 16 CrMo 4 4 | 1501 620 | 2216 | 15 CD 4.5 | - | - | 12CrMo910 | |

| - | 1.7361 | 32CrMo12 | 722 M 24 | 2240 | 30 CD 12 | F.124.A | - | 30CrMo12 | |

| A182 F-22 | 1.7380 | 10 CrMo9 10 | 1501 622 | 2218 | 12 CD 9, 10 | F.155 / TU.H | - | 12CrMo9 10 | |

| 6150 | 1.8159 | 50 CrV 4 | 735 A 50 | 2230 | 50 CV 4 | F.143 | SUP 10 | 50CrV4 | |

| - | 1.8515 | 31 CrMo 12 | 722 M 24 | 2240 | 30 CD 12 | F.1712 | - | 30CrMo12 | |

| - | - | - | - | - | - | - | - | - | |

| Medium Alloy Steel | W1 | 1.1545 | C105W1 | BW1A | 1880 | Y 105 | F.5118 | SK 3 | C100 KU |

| L3 | 1.2067 | 100Cr6 | BL 3 | (2140) | Y 100 C 6 | F.520 L | - | - | |

| L2 | 1.2210 | 115 CrV 3 | - | - | - | - | - | - | |

| P20 + S | 1.2312 | 40 CrMnMoS 8 6 | - | - | 40 CMD 8 +S | X210CrW12 | - | - | |

| - | 1.2419 | 105WCr6 | - | 2140 | 105W C 13 | F.5233 | SKS 31 | 107WCr5KU | |

| O1 | 1.2510 | 100 MnCrW 4 | BO1 | - | 90MnWCrV5 | F.5220 | (SK53) | 95MnWCr5KU | |

| S1 | 1.2542 | 45 WCrV 7 | BS1 | 2710 | 55W20 | F.5241 | - | 45WCrV8KU | |

| 4340 | 1.6582 | 34 CrNiMo 6 | 817 M 40 | 2541 | 35 NCD 6 | F.1280 | SNCM 447 | 35NiCrMo6KB | |

| 5120 | 1.7147 | 20 MnCr 5 | - | - | 20 MC 5 | - | - | - | |

| - | - | - | - | - | - | - | - | - | |

| Tool and High Alloy Steel | D3 | 1.2080 | X210 Cr 12 | BD3 | 2710 | Z200 C 12 | F.5212 | SKD 1 | X210Cr13KU |

| P20 | 1.2311 | 40 CrMnMo 7 | - | - | 40 CMD 8 | F.5263 | - | - | |

| H13 | 1.2344 | X40CrMoV 5 1 | BH13 | 2242 | Z 40 CDV 5 | F.5318 | SKD 61 | X40CrMoV511KU | |

| A2 | 1.2363 | X100 CrMoV 5 1 | BA2 | 2260 | Z 100 CDV 5 | F.5227 | SKD 12 | X100CrMoV51KU | |

| D2 | 1.2379 | X155 CrMoV 12 1 | BD2 | 2310 | Z 160 CDV 12 | F.520.A | SKD11 | X155CrVMo121KU | |

| D4 (D6) | 1.2436 | X210 CrW 12 | BD6 | 2312 | Z 200 CD 12 | F.5213 | SKD 2 | X215CrW121KU | |

| H21 | 1.2581 | X30WCrV9 3 | BH21 | - | Z 30 WCV 9 | F.526 | SKD5 | X30WCrV 9 3 KU | |

| L6 | 1.2713 | 55NiCrMoV 6 | - | - | 55 NCDV 7 | F.520.S | SKT4 | - | |

| M 35 | 1.3243 | S6/5/2/5 | BM 35 | 2723 | 6-5-2-5 | F.5613 | SKH 55 | HS6-5-5 | |

| M 2 | 1.3343 | S6/5/2 | BM2 | 2722 | Z 85 WDCV | F.5603 | SKH 51 | HS6-5-2-2 | |

| M 7 | 1.3348 | S2/9/2 | - | 2782 | 2 9 2 | - | - | HS2-9-2 | |

| HW 3 | 1.4718 | X45CrSi 9 3 | 401 S 45 | - | Z 45 CS 9 | F.3220 | SUH1 | X45CrSi8 | |

| - | 1.7321 | 20 MoCr 4 | - | 2625 | - | F.1523 | - | 30CrMo4 | |

| High Tensile Strength Steel | A128 (A) | 1.3401 | G-X120 Mn 12 | BW10 | 2183 | Z 120 M 12 | F.8251 | SCMnH 1 | GX120Mn12 |

Capabilities of Investment Casting Foundry:

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg – 100 kg

• Annual Capacity: 2,000 tons

• Bond Materials for Shell Building: Silica Sol, Water Glass and their mixtures.

• Tolerances: On Request.

Advantages of Investment Casting Components:

- Excellent and smooth surface finish

- Tight dimensional tolerances.

- Complex and intricate shapes with design flexibility

- Capability to cast thin walls therefore a lighter casting component

- Wide selection of cast metals and alloys (ferrous and non-ferrous)

- Draft is not required in the molds design.

- Reduce the need for secondary machining.

- Low material waste.

| Materials for Investment Casting and CNC Machining at RMC Foundry | |||

| Category | China Grade | US Grade | Germany Grade |

| Ferritic Stainless Steel | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Martensitic Stainless Steel | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Austenitic stainless steel | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 |

302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4406, 1.4408, 1.4409, 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Precipitation Hardening Stainless Steel | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex Stainless Steel | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 |

1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| High Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Tool Steel | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Heat Resistant Steel | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo |

309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Nickle-base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35-1, INCOLOY600, INCOLOY625 |

2.4815, 2.4879, 2.4680 | |

| Aluminum Alloy |

ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Copper Alloy | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 |

C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Cobalt-base Alloy | UMC50, 670, Grade 31 | 2.4778 | |

Also called precision machining, the CNC machining could reach a very high accuracy in geometical tolerance and dimensional tolerance. With our CNC machines and Horizontal Machining Centers (HMC) and Vertical Machining Centers (VMC), we can almost meet all of your required tolerance grades.

| INVESTMENT CASTING TOLERANCES | |||

| Inches | Millimeters | ||

| Dimension | Tolerance | Dimension | Tolerance |

| Up to 0.500 | ±.004″ | Up to 12.0 | ± 0.10mm |

| 0.500 to 1.000” | ±.006″ | 12.0 to 25.0 | ± 0.15mm |

| 1.000 to 1.500” | ±.008″ | 25.0 to 37.0 | ± 0.20mm |

| 1.500 to 2.000” | ±.010″ | 37.0 to 50.0 | ± 0.25mm |

| 2.000 to 2.500” | ±.012″ | 50.0 to 62.0 | ± 0.30mm |

| 2.500 to 3.500” | ±.014″ | 62.0 to 87.0 | ± 0.35mm |

| 3.500 to 5.000” | ±.017″ | 87.0 to 125.0 | ± 0.40mm |

| 5.000 to 7.500” | ±.020″ | 125.0 to190.0 | ± 0.50mm |

| 7.500 to 10.000” | ±.022″ | 190.0 to 250.0 | ± 0.57mm |

| 10.000 to 12.500” | ±.025″ | 250.0 to 312.0 | ± 0.60mm |

| 12.500 to 15.000 | ±.028″ | 312.0 to 375.0 | ± 0.70mm |

Product detail pictures:

Related Product Guide:

With dependable high-quality method, fantastic standing and ideal purchaser assistance, the series of products produced by our firm are exported to many countries and regions for 100% Original Factory Gray Iron Casting Manufacturer - Stainless Steel CNC Machined Pump Housing – RMC Foundry, The product will supply to all over the world, such as: Canada , Paraguay , Bahrain , With the development and enlargement of mass clients abroad, now we have set up cooperative relationships with many major brands. We have our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost products and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.

-

Manufacturer for Gray Iron Sand Casting Product...

-

2020 Latest Design Aluminium No Bake Casting - ...

-

Good User Reputation for Steel Precision Castin...

-

Lowest Price for Casting Foundry - Custom Alum...

-

New Delivery for Bronze Casting Foundry - Grey...

-

Hot sale Alloy Steel Vacuum Casting Foundry - ...