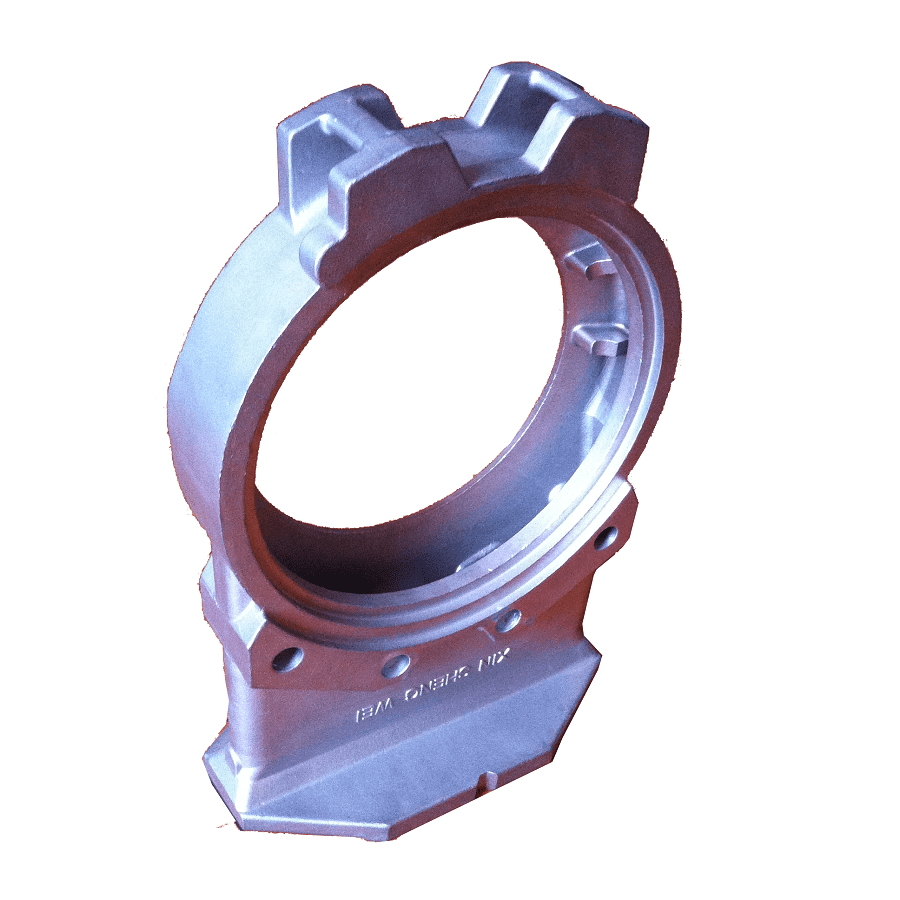

Reasonable price for Stainless Steel Lost Wax Casting Manufacturer - Lost Foam Casting Aluminium Company – RMC Foundry Detail:

Lost foam casting aluminium parts are widely used for transmission cover of heavy duty truck. During lost foam casting process, the sand is not bonded and a foam pattern is used to form the shape of the desired metal parts. The foam pattern is “invested” into the sand at the Fill & Compact process station allowing the sand into all voids and supporting the foam patterns external form. The sand is introduced into the flask containing the casting cluster and compacted to ensure all voids and sapes are supported.

Lost Foam Casting, also called EPC (Expandable Pattern Casting) or LFC (Lost Foam Casting), is to put the foamed plastic pattern group coated with refractory coating into the sand box, and fill it with dry sand or self-hardening sand around the pattern. During pouring, the high-temperature molten metal makes the foam pattern pyrolyzed and “disappears” and occupies the exit space of the pattern, and finally the casting method of the casting is obtained.

The castings produced by lost foam casting have high dimensional accuracy and smooth surface with less pollution in the production process. Lost foam casting is a near-net forming process, suitable for the production of more precise castings of various sizes with complex structures and unlimited alloys.

▶ Raw Materials Available for Lost Foam Casting (LFC):

• Aluminium Alloys.

• Carbon Steel: Low carbon, medium carbon and high carbon steel from AISI 1020 to AISI 1060.

• Cast Steel Alloys: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo…etc on request.

• Stainless Steel: AISI 304, AISI 304L, AISI 316, AISI 316L and other stainless steel grade.

• Brass & Copper.

• Other Materials and Standards on request

▶ Capabilities of Lost Foam Casting Aluminium Foundry

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg – 100 kg

• Annual Capacity: 2,000 tons

• Tolerances: On Request.

Product detail pictures:

Related Product Guide:

Our company since its inception, constantly regards product or service high quality as business life, continually improve creation technology, make improvements to product high-quality and consistently strengthen business total high-quality management, in strict accordance together with the national standard ISO 9001:2000 for Reasonable price for Stainless Steel Lost Wax Casting Manufacturer - Lost Foam Casting Aluminium Company – RMC Foundry, The product will supply to all over the world, such as: Greenland , Russia , United Arab emirates , We pursue the management tenet of "Quality is superior, Service is supreme, Reputation is first", and will sincerely create and share success with all clients. We welcome you to contact us for more information and look forward to working with you.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!

-

High Quality for Steel No Bake Casting - CNC P...

-

China Factory for Brass Sand Casting Foundry - ...

-

China wholesale Duplex Stainless Steel Investme...

-

Factory wholesale Stainless Steel Investment Ca...

-

2020 Good Quality Machining - Cast Stainless S...

-

Best quality Steel Shell Mold Casting Foundry &...