PriceList for Sand Casting Factory - Spheroidal Graphite Cast Iron Casting by Sand Casting – RMC Foundry Detail:

OEM custom nodular cast iron castings by sand casting process.

Ductile cast iron, which is also called nodular cast iron, spheroidal graphite cast iron or just SG iron for short, represent a group of cast iron. Nodular cast iron obtains nodular graphite through spheroidization and inoculation treatment, which effectively improves the mechanical properties of the cast iron, especially the plasticity and toughness, so as to obtain higher strength than carbon steel.

Ductile iron castings have better shock absorption performance than carbon steel, while carbon steel castings have much better weldability. And to some extent, the ductile iorn castings could have some performances of resistanting wear and rust. So the ductile iron casting could be used for some pump housings or water supply systems. However, we still need to make precautions for protecting them from wearing and rust.

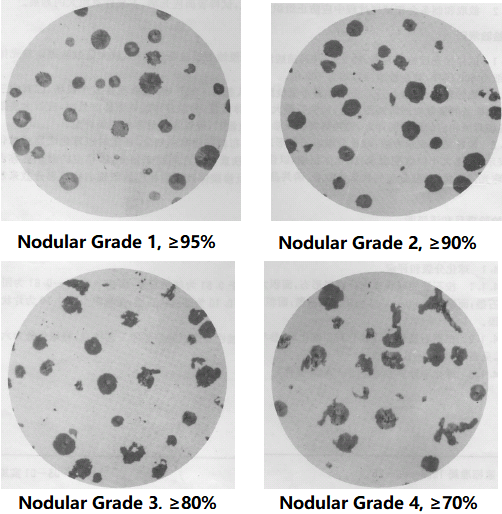

Ductile iron is not a single material but is part of a group of materials which can be produced to have a wide range of properties through control of the microstructure. The common defining characteristic of this group of materials is the shape of the graphite. In ductile irons, the graphite is in the form of nodules rather than flakes as it is in grey iron. The sharp shape of the flakes of graphite create stress concentration points within the metal matrix and the rounded shape of the nodules less so, thus inhibiting the creation of cracks and providing the enhanced ductility that gives the alloy its name. So generally speaking, if the ductile iron could meet your requirements, the ductile iron could be your first choice, instead of carbon steel for your castings.

Raw Materials Available at Sand Casting Foundry of RMC:

• Gray Iron: GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350

• Ductile Iron: GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2

• Aluminium and Their Alloys

• Other Materials and Standards on request

Capabilities of Sand Casting moulded by hand:

• Max Size: 1,500 mm × 1000 mm × 500 mm

• Weight Range: 0.5 kg – 500 kg

• Annual Capacity: 5,000 tons – 6,000 tons

• Tolerances: On Request.

Capabilities of Sand Casting by Automatic Molding Machines:

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg – 500 kg

• Annual Capacity: 8,000 tons – 10,000 tons

• Tolerances: On Request.

Product detail pictures:

Related Product Guide:

We support our consumers with ideal good quality merchandise and large level provider. Becoming the specialist manufacturer in this sector, we have attained wealthy practical encounter in producing and managing for PriceList for Sand Casting Factory - Spheroidal Graphite Cast Iron Casting by Sand Casting – RMC Foundry, The product will supply to all over the world, such as: Monaco , Paris , Tanzania , We would very much welcome an opportunity to do business with you and have pleasure in attaching further details of our products. Excellent quality, competitive prices,punctual delivery and dependable service can be guaranteed.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!

-

professional factory for Precision Casting Manu...

-

Professional Design Zinc Alloy Permanent Castin...

-

Reliable Supplier Ductile Iron Shell Casting Fo...

-

Best quality Ductile Iron Lost Foam Casting Fou...

-

2020 High quality Shell Mold Casting Products -...

-

Wholesale Price Iron Sand Casting Company - Cu...