PriceList for Lost Wax Casting Parts – Brass CNC Machining Parts – RMC Foundry Detail:

Brass CNC machining parts produced by CNC machining centers from China casting company.

▶ Equipment for Precision Brass Machining Components:

• Convertional Machining Machines: 20 sets.

• CNC Machines: 60 sets.

• 3-Axis Machining Center: 10 sets.

• 4-Axis Machining Center: 5 sets.

• 5-Axis Machining Center: 2 sets

▶ Precision Machining Capabilities

• Max Size: 1,500 mm × 800 mm × 500 mm

• Weight Range: 0.1 kg - 500 kg

• Annual Capacity: 10,000 tons

• Accuracy: As per standards: .... or on request. Minimum ±0.003 mm

• Holes to ±0.002 mm dia.

• Flatness, Roundness and Straightness: As per standards or on request.

▶ Our In-house Machining Workshop Give Our Customers the Following Advantages:

• Short lead time for machined castings and forgings.

• Only one contact for castings, forgings and machining.

• Fast transmission between foundry and machining workshop.

• Well communication inside our systems and with our customers.

▶ General Commerial Terms

• Main workflow: Inquiry & Quotation → Confirming Details / Cost Reduction Proposals → Tooling Development → Trial Casting → Samples Approval → Trial Order → Mass Production → Continuous Order Proceeding

• Leadtime: Estimatedly 15-25 days for tooling development and estimatedly 20 days for mass production.

• Payment Terms: To be negotiated.

• Payment methods: T/T, L/C, West Union, Paypal.

| CNC Precision Machining Capabilities | ||||

| Facilities | Quantity | Size Range | Annual Capacity | Accuracy |

| Vertical Machining Center (VMC) | 48 sets | 1500mm × 1000mm × 800mm | 6000 tonn or 300000 pieces | ±0.005 |

| Horizontal Machining Center (VMC) | 12 sets | 1200mm × 800mm × 600mm | 2000 tons or 100000 pieces | ±0.005 |

| CNC Machine | 60 sets | Max turning dia. φ600mm | 5000 tons or 600000 pieces | |

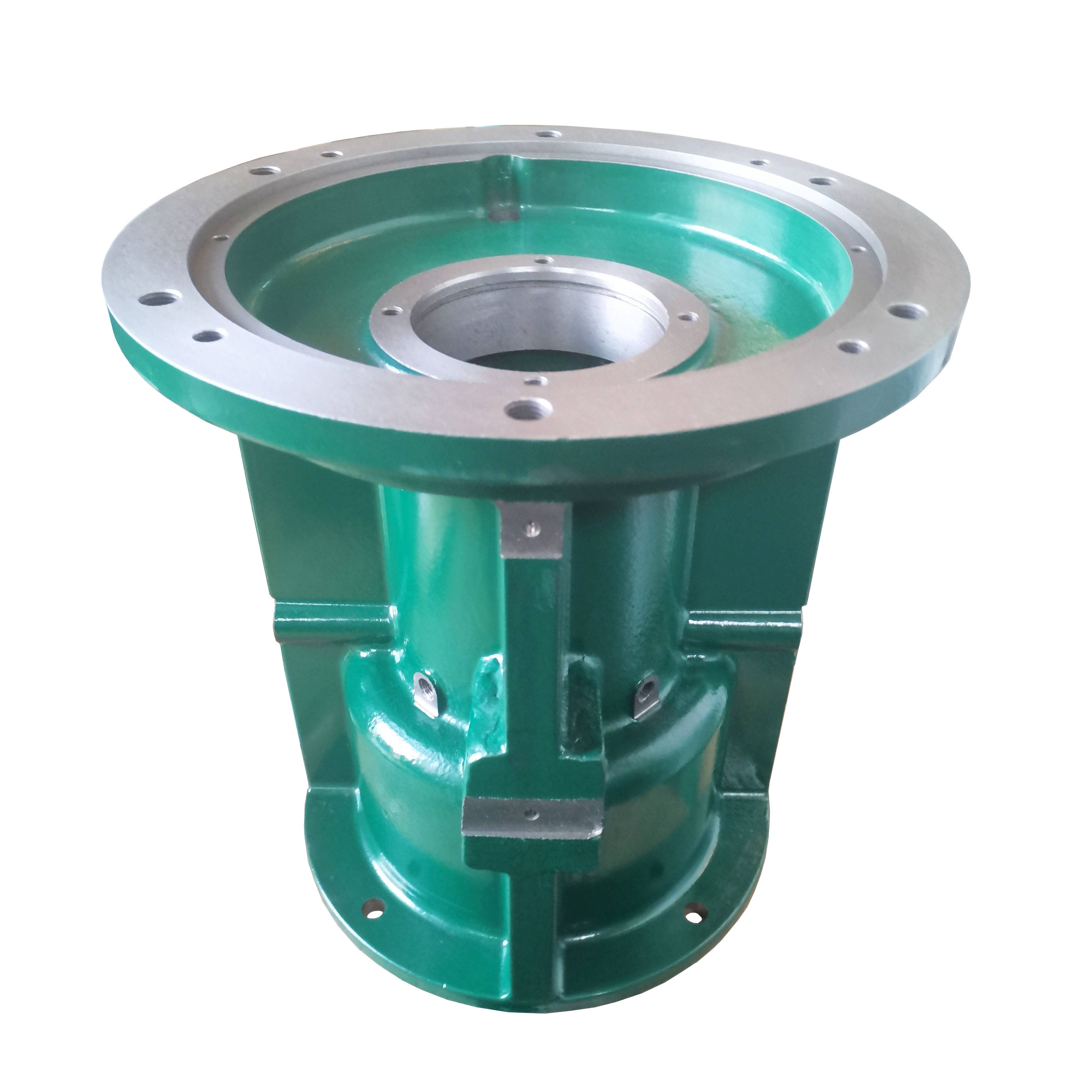

Product detail pictures:

Related Product Guide:

We have the most advanced production equipment, experienced and qualified engineers and workers, recognized quality control systems and a friendly professional sales team pre/after-sales support for PriceList for Lost Wax Casting Parts – Brass CNC Machining Parts – RMC Foundry, The product will supply to all over the world, such as: Gabon , Houston , Miami , Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!