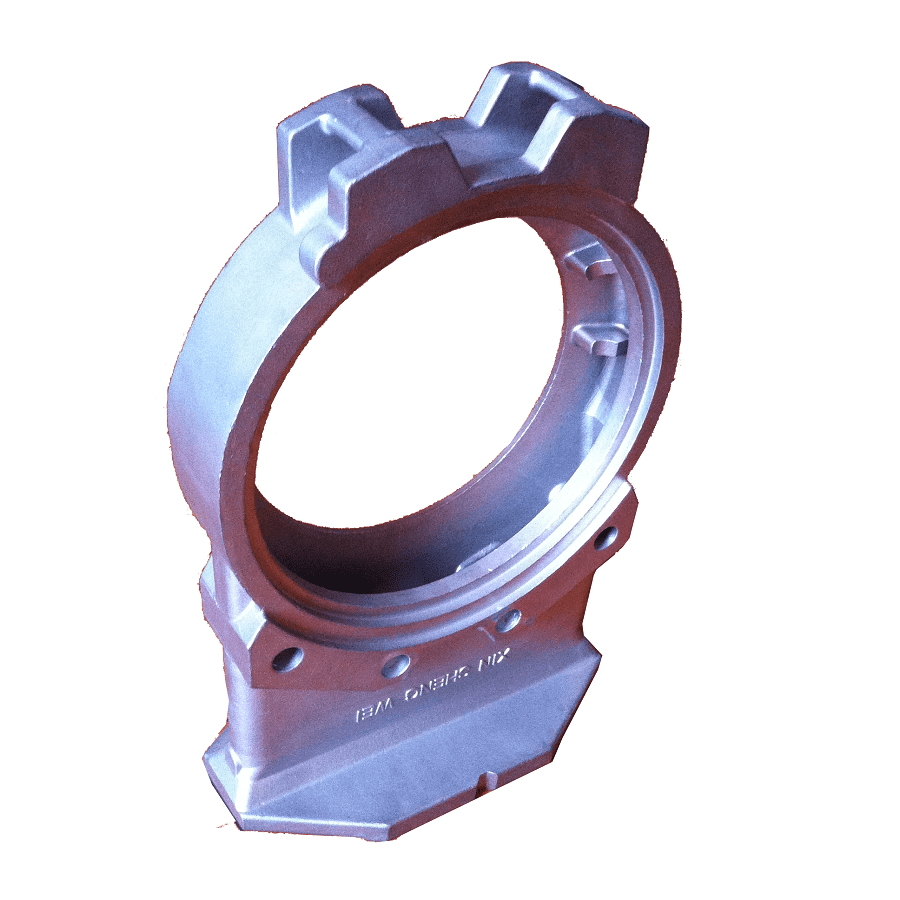

Popular Design for Alloy Steel Casting Factory - Custom Gray Cast Iron Sand Casting – RMC Foundry Detail:

When we cast the gray iron, we strictly follow the chemical composition and mechanical properties according to the stardards or requirements from the customers. Besides, we have the ability and equipment to test if there is casting defects inside the gray iron sand castings.

The ferrous alloys which have carbon contents of more than 2% are called cast irons. Though cast irons can have a carbon percentage between 2 to 6.67, the practical limit is normally between 2 and 4%. These are important mainly because of their excellent casting qualities.

Gray iron castings are cheaper than ductile iron castings, but it has much lower tensile strength and ductility than ductile iron. Gray iron can not replace the carbon steel, while the ductile iron could replace the carbon steel in some situation due the high tensile strength, yield strength and elongation of ductile iron.

From the iron-carbon equilibrium diagram, it can be observed that cast irons have essentially cementite and ferrite. Because of the larger percentage of carbon, the amount of cementite is high resulting in very high hardness and brittleness qualities for cast iron.

▶ What Metals and Alloys We Cast at Our Sand Casting Foundry

• Gray Iron: GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350

• Ductile Iron: GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2

• Aluminium and Their Alloys

• Other Materials and Standards on request

▶ Capabilities of Sand Casting moulded by hand:

• Max Size: 1,500 mm × 1000 mm × 500 mm

• Weight Range: 0.5 kg – 500 kg

• Annual Capacity: 5,000 tons – 6,000 tons

• Tolerances: On Request.

▶ Capabilities of Sand Casting by Automatic Molding Machines:

• Max Size: 1,000 mm × 800 mm × 500 mm

• Weight Range: 0.5 kg – 500 kg

• Annual Capacity: 8,000 tons – 10,000 tons

• Tolerances: On Request.

▶ Main Production Procedure

• Patterns & Tooling Design → Making Patterns → Moulding Process → Chemical Composition Analysis → Melting & Pouring → Cleaning, Grinding & Shot Blasting → Post Processing or Packing for Shipment

▶ Sand Casting Inspection Capabilities

• Spectrographic and manual quantitative analysis

• Metallographic analysis

• Brinell, Rockwell and Vickers hardness inspection

• Mechanical property analysis

• Low and normal temperature impact testing

• Cleanliness inspection

• UT, MT and RT inspection

▶ Post-Casting Process

• Deburring & Cleaning

• Shot Blasting / Sand Peening

• Heat Treatment: Normalization, Quench, Tempering, Carburization, Nitriding

• Surface Treatment: Passivation, Andonizing, Electroplating, Hot Zinc Plating, Zinc Plating, Nickel Plating, Polishing, Electro-Polishing, Painting, GeoMet, Zintec

• Machining: Turning, Milling, Lathing, Drilling, Honing, Grinding,

| Name of Cast Iron

|

Cast Iron Grade | Standard |

| Grey Cast Iron | EN-GJL-150 | EN 1561 |

| EN-GJL-200 | ||

| EN-GJL-250 | ||

| EN-GJL-300 | ||

| EN-GJL-350 | ||

| Ductile Cast Iron | EN-GJS-350-22/LT | EN 1563 |

| EN-GJS-400-18/LT | ||

| EN-GJS-400-15 | ||

| EN-GJS-450-10 | ||

| EN-GJS-500-7 | ||

| EN-GJS-550-5 | ||

| EN-GJS-600-3 | ||

| N-GJS-700-2 | ||

| EN-GJS-800-2 | ||

| Austempered Ductile Iron | EN-GJS-800-8 | EN 1564 |

| EN-GJS-1000-5 | ||

| EN-GJS-1200-2 | ||

| SiMo Cast Iron | EN-GJS-SiMo 40-6 | |

| EN-GJS-SiMo 50-6 |

Product detail pictures:

Related Product Guide:

Our pros are lessen prices,dynamic sales team,specialised QC,sturdy factories,top quality services and products for Popular Design for Alloy Steel Casting Factory - Custom Gray Cast Iron Sand Casting – RMC Foundry, The product will supply to all over the world, such as: Croatia , Azerbaijan , Namibia , Thus far, our item associated with printer dtg a4 may be shown in most foreign nations as well as urban centers, which are sought after simply by targeted traffic. We all highly imagine that now we have now the full capacity to present you with contented merchandise. Desire to collect requests of your stuff and produce the long-term co-operation partnership. We very seriously promise:Csame top quality, better price; exact same selling price, higher quality.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!

-

High Quality Steel Investment Casting - Custom...

-

New Arrival China Gray Iron Shell Mold Casting ...

-

Short Lead Time for Zinc Alloy Gravity Casting ...

-

Best Price for Copper Foundry - Grey Cast Iron...

-

Wholesale Price Duplex Stainless Steel Precisio...

-

Discount Price Gray Iron Casting Supplier - Al...