-

Custom Cast Stainless Steel Product

Cast Metal: Stainless Steel, Wear Resistant Steel, Heat Resistant Steel

Casting Process: Investment Casting, Lost Wax Casting

Unit Weight of Casting: 13.60 kg

Application: Pump Housing

Surface Treatment: Shot Blasting + Machining + Painting

Heat Treatment: Annealing + Solution

OEM custom cast stainless steel products with CNC machining and surface treatment services. Our casting foundry are making our efforts to optimize the casting costs by applying suitable casting technologies and developing the best engineering solutions with respect to the usability features of the final stainless steel investment castings.

-

Stainless Steel Lost Wax Casting Product

Material: Stainless Steel AISI 316 / CF8M / 1.4408

Casting Manufacturing: Lost Wax Investment Casting + CNC Machining

Application: Valve Body

Weight: 18.50 kg

Heat Treatment: Annealing + Solution

Stainless steel AISI 316 / CF8M / 1.4408 lost wax investment casting valve body in China casting foundry with custom CNC machining services based on your requirements and drawings.

-

CrMo Alloy Steel Investment Casting

Casting Metals: Cast CrMo Alloy Steel

Casting Manufacturing: Investment Casting (Lost Wax Casting Process)

Application: Connector

Weight: 2.60 kg

Chromium-molybdenum cast steel has very good high temperature performance and creep resistance. After quenching and tempering or normalizing heat treatment, chromium-molybdenum cast steel can obtain excellent mechanical properties. Molybdenum can improve the hardenability of cast steel and reduce the temper brittleness of cast steel. Chromium-molybdenum cast steel is used for large-section castings and steel castings that require deep hardening.

-

Precipitation Hardening Stainless Steel Casting

Material: Precipitation Hardening Stainless Steel 17-4PH

Casting Process: Investment Casting

CNC Machining: Available

Application: Pump Housing, Machinery Parts

OEM custom precipitation hardening stainless steel casting products produced by investment casting. We can also offer CNC machining, heat treatment, surface treatment, testing and assembly services. Precipitation hardening stainless steel is widely used in advanced industries. For example, the typical precipitation hardening stainless steel 17-4PH can be used to make structures below 370°C that require corrosion resistance, wear resistance, and high strength.

-

Carbon Steel Lost Foam Casting

- Casting Material: Cast Carbon Steel

- Casting Process: Lost Foam Casting ( Full Mold Casting )

- Surface: Sand Blasting

- Weight: 6.80 kg

Carbon steel lost foam casting products from China manufacturer. As one of the most-advanced steel foundries with lost foam casting, sand casting and investment casting processes, we are here to produce the high level of precision and dimensional accuracy with consistently high quality and efficiency.

-

Duplex Stainless Steel Lost Wax Casting

Casting Metals: Duplex Stainless Steel 2205

Manufacturing Process: Investment Casting + CNC Machining

Application: Connector

Weight: 6.60 kg

Heat Treatment: Annealing + Solution

Duplex stainless steel casting from China investmnet casting foundry with OEM custom engineering services based on your requirements and drawings. Request a quote today on lost wax castings for your precision parts, or contact us for more information. Available grade of duplex stainless steel: 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770, A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507, 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N. The DSS has the characteristics of austenitic and ferritic stainless steel. Compared with ferrite, it has higher plasticity and ductility, no room temperature brittleness, and significantly improved intergranular corrosion resistance and welding performance, while still maintaining brittleness, high thermal conductivity, and superplasticity as ferrite stainless steel.

-

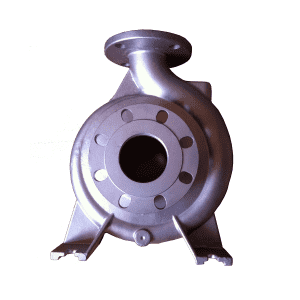

Stainless Steel Investment Casting Pump Body

Material: Stainless Steel AISI 316 / CF8M

Casting Manufacturing: Investment Casting + CNC Machining

Application: Pump Body

Weight: 28.50 kg

Heat Treatment: Annealing + Solution

Stainless steel AISI 316 / CF8M casting pump body in China casting foundry with custom CNC machining services based on your requirements and drawings. CF8M is defined in ASMT A351, ASMT A743 and ASTM A744, which is for casting purpose only. SS 316 is defined in ASTM A240 and ASTM A276, it’s for plate, sheet, strip or stainless steel bars. Another grade is named as F316, which is from ASTM A182 for forged parts only. TP316 will be found in ATSTM A376 for pipe only. The main applications of CF8M cast stainless steel cover: impellors, propellers, pump casings, valve bodies and press plates.

-

Wear-resistant Alloy Steel 35CrMo, 42CrMo Casting

- Material: Wear-resistant Alloy Steel 30CrMo, 35CrMo, 42CrMo

- Casting Process: Sand Casting + CNC Machining

- Application: Heavy Duty Trucks

- CNC Machining: Available

- Heat Treatment: Annealing, Quenching, Normalizing, Carburizing, Nitriding, Carbonitriding

- Unit Weight: 4.20 kg

OEM custom alloy steel sand castings made of wear-resistant alloy steel in China casting foundry. Wear-resistant (or abrasion-resistant) cast steel is a type of cast steel. It refers to the cast steel with good wear resistance. According to chemical composition, it is divided into non-alloy, low-alloy and alloy wear-resistant cast steel. There are many types of wear-resistant steel, which can be roughly divided into high-manganese steel, medium and low-alloy wear-resistant steel, chromium-molybdenum-silicon-manganese steel, cavitation-resistant steel, wear-resistant steel, and special wear-resistant steel.

-

Cast Carbon Steel Castings with CNC Machining

- Material: Cast Carbon Steel

- Casting Process: Investment Casting + CNC Machining

- Application: Heavy Duty Trucks

- CNC Machining: Available

- OEM Custom Service: Available

- Unit Weight: 4.20 kg

The strength and hardness of cast carbon steel increase with the increase of carbon content. Cast carbon steel has the following advantages: lower production cost, higher strength, better toughness and higher plasticity. Cast carbon steel can be used to manufacture parts that bear heavy loads, such as steel rolling mill stands and hydraulic press bases in heavy machinery. It can also be used to manufacture parts that are subject to large forces and impact, such as wheels, couplers, bolsters and side frames on railway vehicles.

-

Carbon Steel Precision Investment Casting

- Material: Carbon Steel

- Casting Process: Investment Casting

- Application: Trucks

- CNC Machining: Available

- OEM Custom Service: Available

- Unit Weight: 3.20 kg

Cast carbon steel is the kind of cast steel with carbon as the main alloying element and a small amount of other elements. Cast carbon steel can be divided into cast low carbon steel, cast medium carbon steel and cast high carbon steel. The carbon content of cast low carbon steel is less than 0.25%, the carbon content of cast carbon steel is between 0.25% and 0.60%, and the carbon content of cast high carbon steel is between 0.6% and 3.0%.

-

Stainless Steel 316 / 1.4408 Casting Valve Disc

Casting Metals: Stainless Steel AISI 316, CF8M, 1.4408

Casting Manufacturing: Investment Casting + CNC Machining

Application: Butterfly Valve Disc

Weight: 9.50 kg

Heat Treatment: Annealing + Solution

Stainless steel butterfly valve disc with grade of AISI 316, 1.4408 or CF8M in China investment casting foundry with custom CNC machining services based on your requirements and drawings. Full solution from one single supplier ranging customized pattern design to finished castings and secondary process including CNC machining, heat treatment and surface treatment.

-

Duplex Stainless Steel 2205 / 2507 Investment Casting

Casting Metals: Duplex Stainless Steel 2205, 2507, 2304, 1.4462

Manufacturing Process: Investment Casting + CNC Machining

Application: Pipe Fittings

Weight: 15.60 kg

Heat Treatment: Annealing + Solution

Duplex stainless steel (DSS) 2205/2507/2304/1.4462 castings from China investmnet casting foundry with OEM custom engineering services based on your requirements and drawings.