-

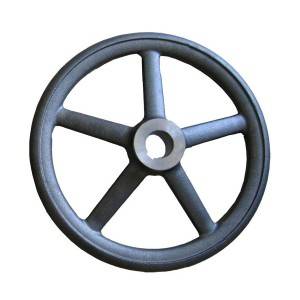

Custom Alloy Steel V Process Casting Product

- Casting Metals: Cast Alloy Steel

- Casting Manufacturing: Vacuum (V Process) Casting

- Weight: 8.60 kg

- Heat Treatment: Annealing + Quenching + Tempering

China OEM custom alloy steel vacuum casting products with services of heat treatment, surface treatment and CNC machining. Available surface treatment: Painting, Anodizing, Passivation, Electroplating, Zinc-plating, Hot-Zinc-Plating, Polishing, Electro-Polishing, Nickel-Plating, Blackening, Geomet, Zintek

-

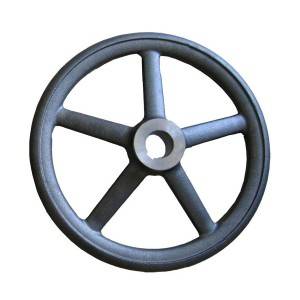

Carbon Steel Vacuum Casting Product

Cast Steel: Cast Carbon Steel

Casting Process: Vacuum Casting (V Process Casting)

Unit Weight of Casting: 12.60 kg

Surface Treatment: Shot Blasting + Machining + Painting

Heat Treatment: Annealing + Tempering + Quenching

OEM custom carbon steel casting products by vacuum (v process) process with CNC machining and surface treatment services. Available inspection methods: dimension testing by CMM, non-destructive testing, chemical composition, mechanical properties, hardness testing, static balancing, dynamic balancing, air pressure and water pressure.

-

Alloy Steel Lost Foam Casting Product

Material: Alloy Steel, Cast Steel

Casting Process: Lost Foam Casting + CNC Machining

Unit Weight: 15.20 kg

Application: Truck Spare Parts

Alloy steel lost foam casting product supplies from China casting company with CNC machining services and OEM custom services. Just feel free to contact us if you need a free quotation for your custom castings. Available inspection methods: dimension testing by CMM, non-destructive testing, chemical composition, mechanical properties, hardness testing, static balancing, dynamic balancing, air pressure and water pressure.

-

OEM Custom Cast Steel Sand Castings

- Cast Steel: Alloy Steel, Carbon Steel, Stainless Steel

- Casting Process: Sand Casting

- Unit Weight of Casting: 6.60 kg

- Application: Exhaust Bending Pipe

- Surface Treatment: Shot Blasting + Machining + Painting

- Heat Treatment: Annealing + Tempering + Quenching

OEM custom cast steel casting products by sand casting process with CNC machining and surface treatment services. Available inspection methods: dimension testing by CMM, non-destructive testing, chemical composition, mechanical properties, hardness testing, static balancing, dynamic balancing, air pressure and water pressure.

-

Custom Steel Sand Casting Product

- Cast Metal: Alloy Steel, Carbon Steel, Stainless Steel

- Casting Process: Sand Casting

- Unit Weight of Casting: 8.60 kg

- Application: Machinery Parts

- Surface Treatment: Shot Blasting + Machining + Painting

- Heat Treatment: Annealing + Tempering + Quenching

OEM custom steel casting products by sand casting process with CNC machining and surface treatment services. Available inspection methods: dimension testing by CMM, non-destructive testing, chemical composition, mechanical properties, hardness testing, static balancing, dynamic balancing, air pressure and water pressure.

-

Custom Duplex Stainless Steel CD3MWCuN Investment Casting Product

Material: Duplex Stainless Steel CD3MWCuN, 2205, 2507

Casting Process: Lost Wax Investment Casting

CNC Machining: Available

OEM Custom Service: Available

Finish: Polishing

Heat Treatment: Annealing, Solution, Quenching, Normalizing, Carburizing, Nitriding, Carbonitriding

Unit Weight: 4.20 kg

OEM custom duplex stainless steel investment castings with available surface treatment: Painting, Anodizing, Passivation, Electroplating, Zinc-plating, Hot-Zinc-Plating, Polishing, Electro-Polishing, Nickel-Plating, Blackening, Geomet, Zintek

-

Custom Carbon Steel Investment Casting Product

Material: Carbon Steel C30, C40, C45

Casting Process: Lost Wax Investment Casting

Application: Valve and Pump Parts

CNC Machining: Available

OEM Custom Service: Available

Heat Treatment: Annealing, Quenching, Normalizing, Carburizing, Nitriding, Carbonitriding

Unit Weight: 4.20 kg

Available surface treatment: Painting, Anodizing, Passivation, Electroplating, Zinc-plating, Hot-Zinc-Plating, Polishing, Electro-Polishing, Nickel-Plating, Blackening, Geomet, Zintek

-

Stainless Steel Lost Wax Casting Product

- Casting Metals: Stainless Steel, Cast Steel, Alloy Steel, Wear and Heat Resistant Steel

- Casting Manufacturing: Precision Lost Wax Investment Casting

- Application: Connector

- Weight: 1.60 kg

- Heat Treatment: Annealing + Solution

Stainless steel investment castings from China lost wax casting manufacturer with OEM custom engineering services based on your requirements and drawings. Our engineering experts are happy to help you develop the optimum solutions for your company with Chinese price level but reliable quality.

-

Cast Stainless Steel Investment Casting Product

- Material: Cast Stainless Steel

- Casting Process: Precision Investment Casting

- Unit Weight: 5.20 kg

- Application: Connector

Cast stainless steel parts produced by precision lost wax investment casting in China steel foundry. Cuctom services and CNC machining are available. CF8M is a cast austenitic stainless steel which covered by ASTM A351, ASTM A743 and ASTM A744 standard. CF8M equal to SS 316/F 316 and Chinese Standard 0Cr17Ni12Mo2. CF8M is a molybdenum bearing modification of CF8 alloy and is the cast equivalent of wrought AISI 316 Stainless steel.

-

China AISI 304 Stainless Steel Investment Casting Impeller

- Material: 304, 316 Stainless Steel

- Manufacturing Process: Investment Casting + CNC Machining

- Application: Impeller

- Heat Treatment: Solution

Custom stainless steel investment casting foundry from China with CNC machining services. We look forward to your questions or RFQ. Austenitic 304 stainless steel steel plate, which is said to bring strong anti-rust and corrosion resistance, and has excellent plasticity and toughness, which is convenient for stamping and forming. With a density of 7.93 g/cm3, 304 stainless steel is a very common stainless steel, also known as 18/8 stainless steel in the industry. Its metal products are resistant to high temperatures and have good processing properties, so they are widely used in industry and furniture decoration industries and food and medical industries.

-

OEM Carbon Steel Investment Casting Product

- Cast Metal: Low Carbon Steel, Medium Carbon Steel, High Carbon Steel

- Casting Process: Lost Wax Investment Casting

- Unit Weight of Casting: 8.60 kg

- Surface Treatment: Shot Blasting + Machining

- Heat Treatment: Annealing + Quenching + Tempering

OEM custom carbon steel lost wax investment casting products with CNC machining and surface treatment services. Our investment casting foundry are making our efforts to optimize the casting costs by applying suitable casting technologies and developing the best engineering solutions with respect to the usability features of the final carbon steel castings.

-

Alloy Steel Lost Wax Casting Product

Cast Metal: Alloy Steel, Carbon Steel, Stainless Steel

Casting Process: Lost Wax Casting

Unit Weight of Casting: 8.60 kg

Surface Treatment: Shot Blasting + Machining

Heat Treatment: Annealing + Quenching + TemperingOEM custom alloy steel lost wax casting products with CNC machining and surface treatment services. Our investment casting foundry are making our efforts to optimize the casting costs by applying suitable casting technologies and developing the best engineering solutions with respect to the usability features of the final alloy steel castings.