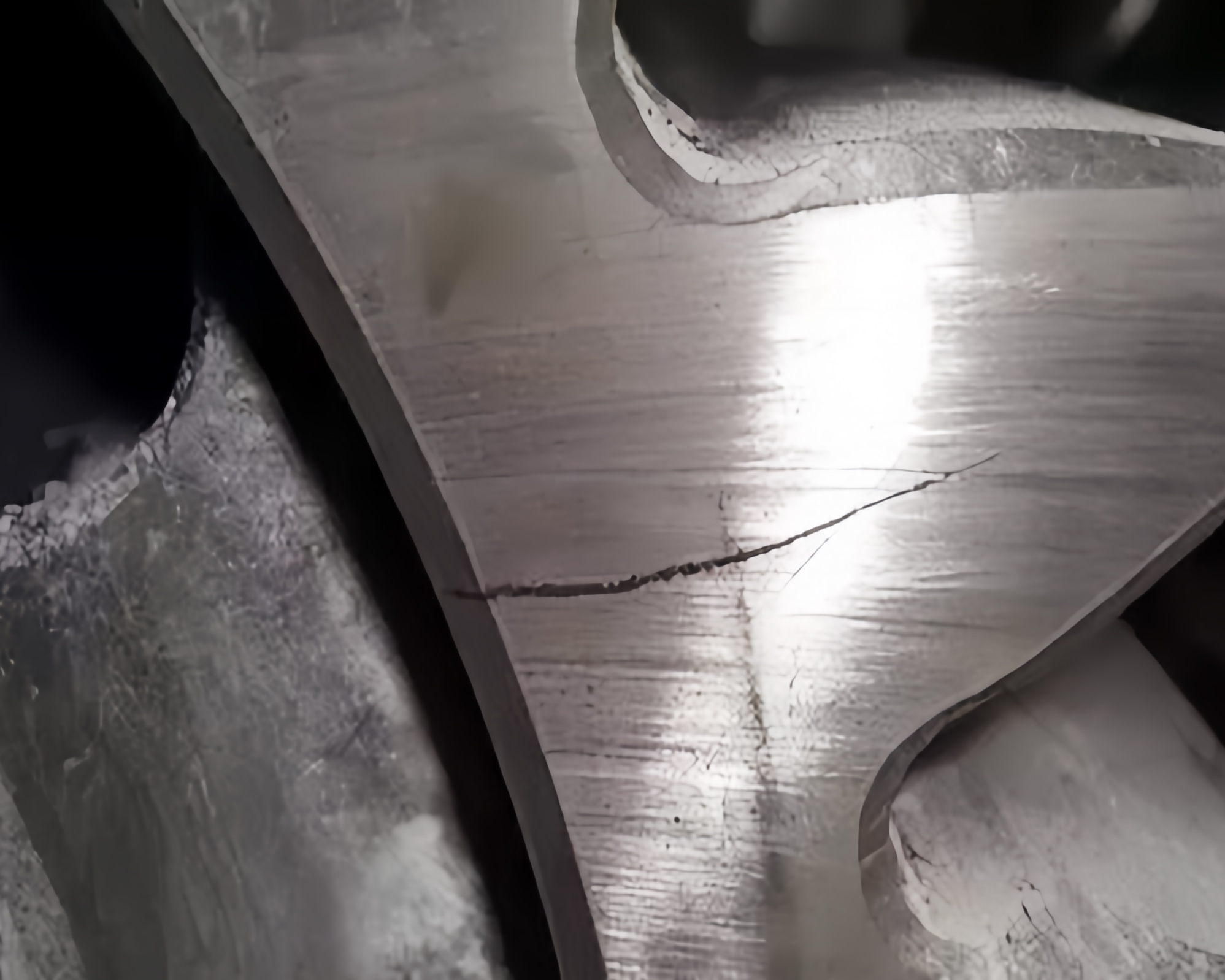

Hot cracks propagate along grain boundaries, exhibiting a tortuous shape with an oxidized, rough surface. These cracks form near the solidus temperature within the solidification range of the alloy when it is in a hot brittle state. Investment casting of superalloys and sand casting of large castings are prone to hot cracking. In contrast, lost foam casting has a lower tendency for hot cracking.

Hot cracks can be classified into external and internal cracks:

• External cracks: Typically occur in casting sections with abrupt thickness changes or in hot spots where local solidification is slower.

• Internal cracks: Form in the last solidified regions inside the casting, often near or at the tail end of shrinkage cavities.

Hot cracking not only reduces the mechanical properties of the metal but also causes stress concentration, leading to potential failure of the casting due to crack propagation during use.

.jpg)

Theories Explaining the Mechanism of Hot Cracking

1. Liquid Film Theory: When the casting cools near the solidus temperature, a thin liquid film remains around the grains. If the casting’s shrinkage is restricted, deformation is concentrated in the liquid film. Once this deformation reaches a critical value, the liquid film ruptures, forming intergranular cracks.

2. Strength Theory: During solidification, the casting may be unable to shrink freely due to restrictions from the mold, core, gating system, or risers. If the internal stress or strain exceeds the fracture strength or fracture strain of the metal at that temperature, hot cracking occurs.

Measures to Prevent Hot Cracking

1. Reduce the content of harmful elements in the alloy, such as minimizing sulfur and phosphorus in steel.

2. Ensure thorough deoxidation during alloy melting.

3. Reduce non-metallic inclusions.

4. Improve the collapsibility of molds and cores.

5. Properly arrange core supports and mold bands.

6. Ensure that the gating system and risers do not obstruct the shrinkage of the casting. Use chill molds to accelerate the cooling of hot spots.

7. Maintain uniform wall thickness in castings, provide smooth transitions at thickness variations, and use fillets at right-angle junctions.

8. Apply anti-crack ribs and other preventive measures.

Post time: Feb-08-2025