Due to the liquid shrinkage and solidification shrinkage of metal melts, cavities typically appear in the final solidification areas of castings. Large and concentrated cavities are called shrinkage cavities, while small and dispersed cavities are referred to as shrinkage porosity. Investment casting inevitably develops shrinkage cavities and shrinkage porosity when the alloy has a high shrinkage rate or the casting structure is not properly designed.

Shrinkage Cavities

Shrinkage cavities often occur in pure metals, eutectic composition alloys, and alloys with a narrow solidification temperature range. They are mostly concentrated in the upper part of the casting and the final solidification area or in thick-walled sections, intersections of walls, and areas near the inner gating system where solidification is slow (these areas are called hot spots).

Based on their location in the casting, shrinkage cavities can be classified into internal shrinkage cavities and external shrinkage cavities.

• External shrinkage cavities appear on the surface or top of the casting, usually forming a funnel shape in the upper part of the casting.

• Internal shrinkage cavities are formed within the casting.

.jpg)

Shrinkage Porosity

Shrinkage porosity commonly occurs in alloys with a wide solidification temperature range. It is often distributed in broader regions near the casting’s central axis or around shrinkage cavities.

Shrinkage porosity can be classified based on its morphology and distribution:

By morphology:

• Macroscopic shrinkage porosity (commonly referred to as shrinkage porosity): Visible to the naked eye.

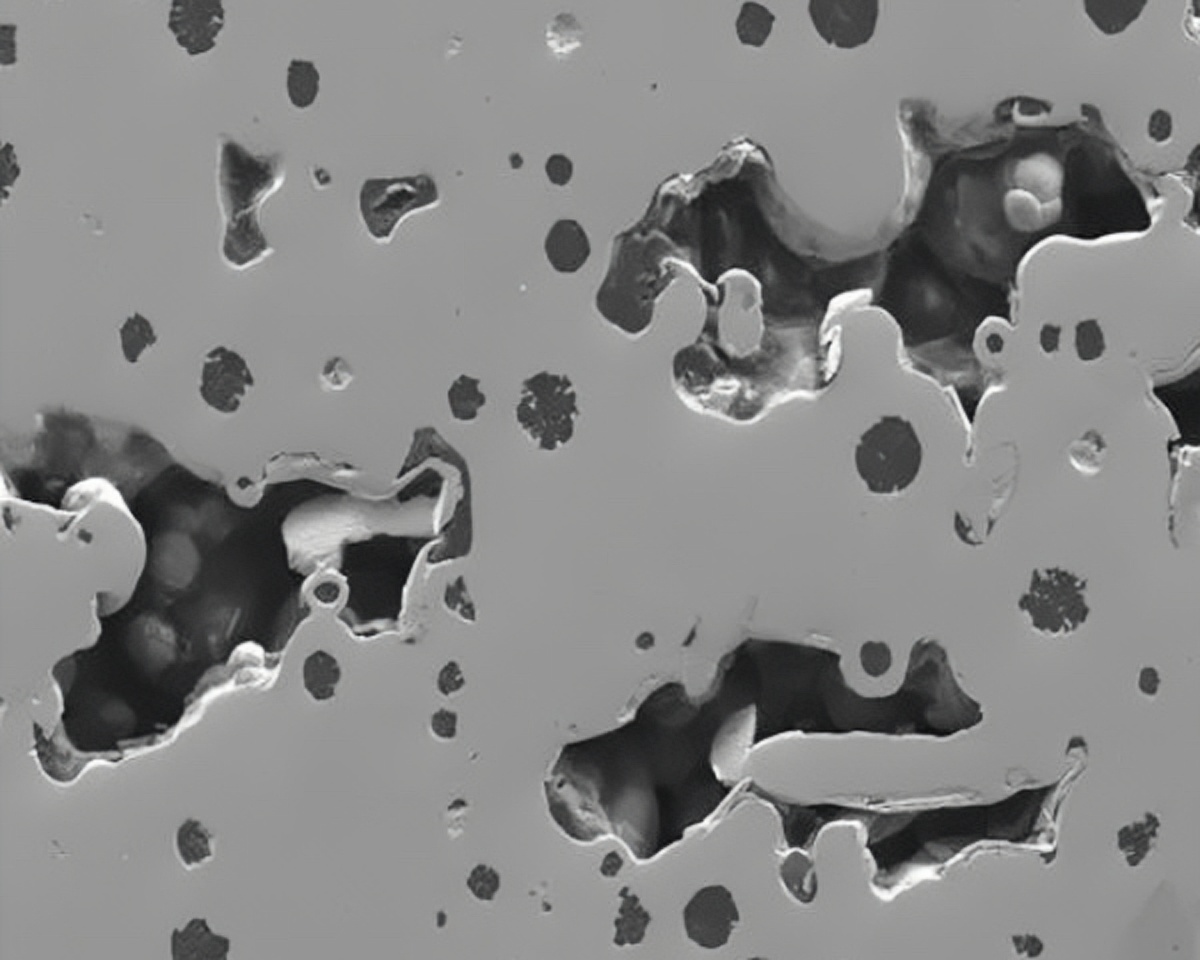

• Microscopic shrinkage porosity (also known as micro-shrinkage porosity): Can only be observed under a microscope. It typically appears in interdendritic or subdendritic regions of various castings.

By distribution:

• Dispersed shrinkage porosity: Spread throughout the entire cross-section of the casting.

• Axial shrinkage porosity: Occurs in the area near the casting’s central axis.

• Localized shrinkage porosity: Appears in specific areas of the casting, such as thick sections, the root of risers, and near the inner gating system.

Impact of Shrinkage Cavities and Shrinkage Porosity

Sand casting is more prone to shrinkage cavities and shrinkage porosity due to its slow cooling rate, limited feeding ability, and alloy characteristics. The presence of shrinkage cavities and shrinkage porosity reduces the effective load-bearing area of the casting and creates stress concentration at sharp corners of these defects. Both types of defects significantly decrease the mechanical properties of castings. Additionally, shrinkage cavities and shrinkage porosity lower the castings' gas tightness and physical-chemical properties. Therefore, they are considered serious casting defects.

Post time: Mar-21-2025