Austempered ductile iron, also known as ADI, refers to the ductile cast iron after process of austenitizing ductile iron (850℃-950℃) and then quickly placing it in a salt bath (232℃-450℃) for isothermal transformation. In addition, with the addition of sufficient amounts of Cu, Ni, Mo and other elements, austempered austenitic ductile iron can also be obtained under continuous cooling conditions.

Austempered ductile iron castings have excellent mechanical properties, and their unit weight of yield strength is the smallest. The obtaining of different grades of austempered ductile iron depends on the temperature of austempering and has nothing to do with the chemical composition. Generally speaking, the chemical composition of austempered ductile iron is in the following range:

C: 3.5%-3.8%

Si: 2.4%-3.0%

Mn: <0.30%

P: <0.07%

S: <0.02%

Silicon is one of the most important elements of austempered ductile iron. Silicon prevents the formation of Bainite carbides, thereby contributing to the formation of acicular ferrite. Increasing the silicon content can increase the impact toughness of austempered ductile cast iron and reduce elongation. The role of Manganese has two sides. On the one hand, it can greatly improve the hardenability; on the other hand, Manganese will promote the formation of carbides and hinder the isothermal transformation during the solidification process. Therefore, when the number of graphite spheres is low and the wall thickness is large, the segregation of manganese at the grain boundary will cause shrinkage porosity, carbides and unstable austenite in the ductile iron casting. These microstructure defects and inhomogeneities will reduce the machinability and mechanical properties. Therefore, the mass percentage of manganese should be controlled below 3%.

In actual casting production, in order to obtain stable and high-quality austempered ductile iron castings, there are two points that need special attention:

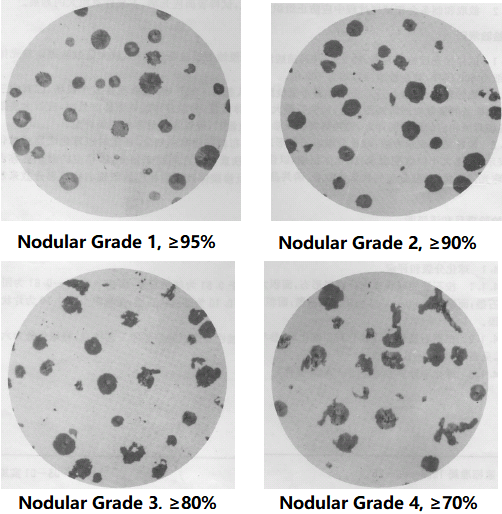

1) Control the structure of as-cast ductile iron before isothermal treatment. The spheroidization rate should be higher than 80%. The number of graphite pheres should be more than 100 per square millimeter. Other conditions include: stable chemical composition; the casting should be basically free of carbides, porosity and inclusions; and a stable pearlite/ferrite content ratio.

2) Determine the appropriate heat treatment specifications according to the composition and as-cast structure of ductile iron, and carry out a strict and stable austempering heat treatment process

Post time: Apr-15-2021