The lost foam casting process eliminates the need for sand binders and cores. The sand is unbonded and a foam pattern is used to form the shape of the casting. The foam pattern is "invested" into the sand at the Fill & Compact process station allowing the sand into all voids and supporting the foam patterns external form. The sand is introduced into the flask containing the casting cluster and compacted to ensure all voids and shapes are supported.

The flask is transported to the pouring operation. The foam is evaporated as the metal is poured allowing the metal to take the shape of the casting cluster. Separation of sand and metal is accomplished at a Flask Dump Station. With no binders in the sand this process is performed with ease. Systems can be designed to accommodate quenching operations if required. The cluster proceeds to the casting finishing area for sprue, gate and riser removal. The sand is reprocessed by classification and cooling to be re-used. Thermal reclamation of the sand will extend the useful life. Lost Foam offers an environmentally friendly process with the added advantage of more accurate castings.

Foam patterns are created from polystyrene beads. The beads start as hard granules, very similar in size and shape to sand granules. The beads are expanded, allowed to stabilize and then molded into the desired shape. More complex shapes require multiple patterns to be glued together. The assemblies are then attached to a generic, central foam piece called a tree. Multiple patterns can be produced on a single tree. After assembly, the entire tree is dipped into a refractory coating to strengthen the tree. The assembled, strengthened tree is attached to a pouring funnel (called a sprue) and placed into the flask.

RMC is recognized as the leading casting company in lost foam technology. We provide a comprehensive line of lost foam equipment, including flask pouring, flask handling and flask compaction. Our line of foam bead processing equipment is recognized world wide as the industry standard. Below are some of the items we design and manufacture for the lost foam process.

Sand Processing Equipment

Sand Processing Equipment

Sand Processing Equipment

Foam Patterns

Foam Patterns

Foam Patterns

Foam Patterns

Lost Foam Master

Lost Foam Master

Lost Foam Master

Foam Master-Cluster Coating

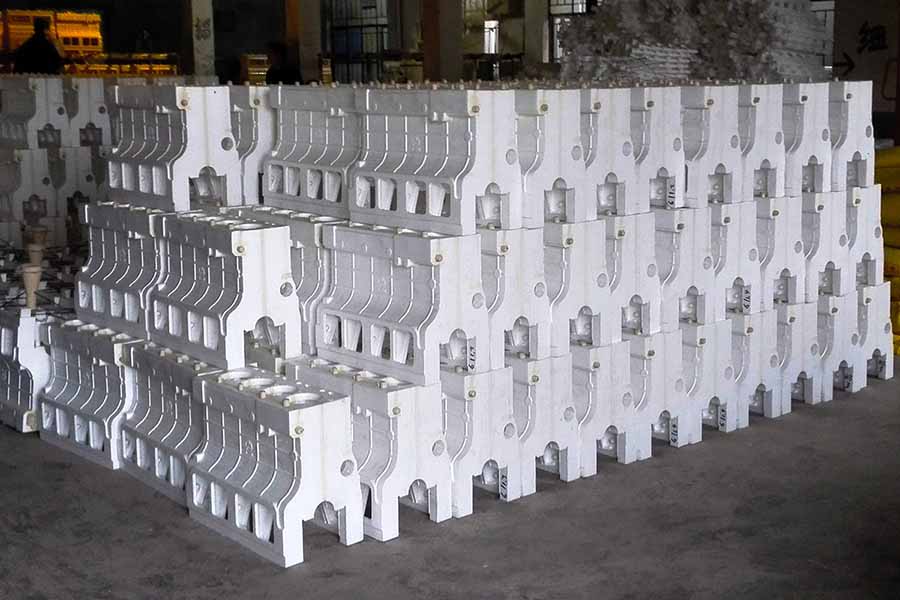

Lost Foam Casting Pattern

Grey Iron Lost Foam Casting Parts

Cast Iron Lost Foam Castings

Gray Iron Lost Foam Castings